Gravity Casting Machine

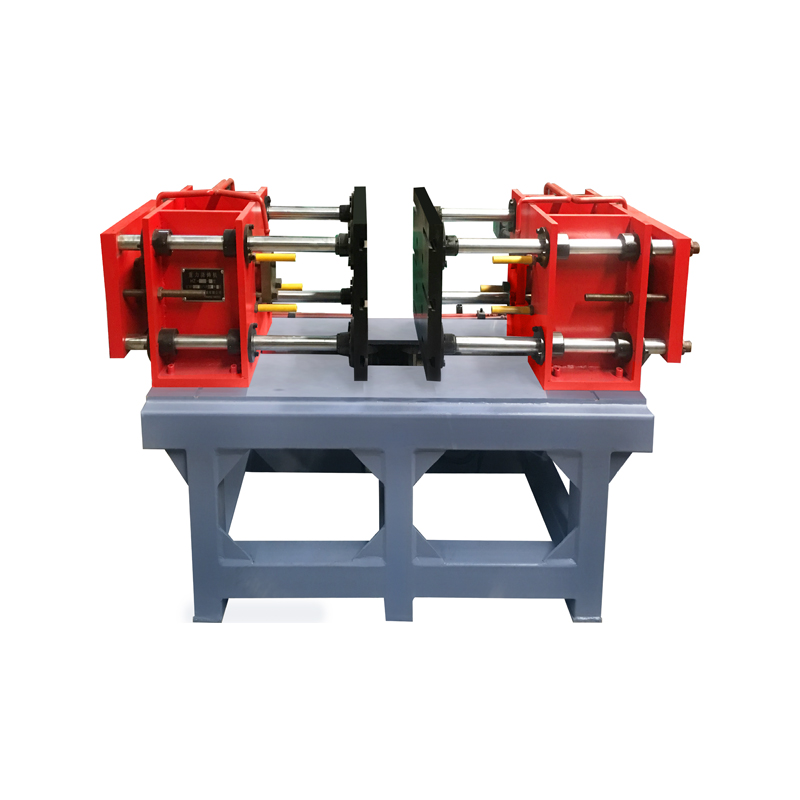

HZ650-2D Horizontal Parting Gravity Casting Machine

The Horizontal Parting Gravity Casting Machine is an essential tool in the foundry industry, designed for producing high-precision castings with Individual cases surface finishes. This machine features a horizontal parting design that optimizes the mold filling process, ensuring efficient and consistent results.

Key Features of the Horizontal Parting Gravity Casting Machine

Efficient Mold Filling Process

The horizontal parting system ensures that the mold cavity is filled evenly, A significant reduction the risk of air pockets and defects. This gravity-fed approach allows for a controlled and smooth casting process, resulting in high-quality products.

Enhanced Productivity

Designed to reduce cycle times, the Horizontal Parting Gravity Casting Machine can significantly increase the productivity of foundries. By offering quick setup times, easy operation, and Very small downtime, this machine helps manufacturers maintain continuous production while reducing labor costs and increasing output efficiency.

Versatile Applications

This casting machine is ideal for producing a wide variety of products, including automotive parts, industrial components, and machinery fittings. Its versatility makes it a valuable asset for companies across different sectors, allowing them to diversify their product offerings and meet the demands of a rapidly changing market.

High Precision and Quality

One of the protrude features of the Horizontal Parting Gravity Casting Machine is its ability to produce castings with Individual cases dimensional accuracy. The high level of precision achieved during the casting process ensures that the final product meets strict quality standards and is suitable for industries where reliability is .

Durability and Reliability

Built with robust materials, the Horizontal Parting Gravity Casting Machine is designed to withstand the harsh conditions of continuous operation. Its durable construction ensures long-term reliability, making it a solid investment for any foundry looking to enhance its casting capabilities.

User-Friendly Operation

The machine’s intuitive control system and automated features simplify operation, allowing operators to quickly adjust settings for different casting requirements. This ease of use helps reduce the chances of human error and improves overall process consistency.

Cost-Effective Solution

Offering a balance of performance and affordability, the Horizontal Parting Gravity Casting Machine is ideal solution for foundries aiming to optimize their production without significant capital investment. Its efficiency in terms of both time and resources results in lower operational costs over time.

Why Choose the Horizontal Parting Gravity Casting Machine?

The Horizontal Parting Gravity Casting Machine stands out due to its combination of precision, versatility, and durability. Its design As small as possible the need for additional equipment, making it a compact solution for many foundries.

The Horizontal Parting Gravity Casting Machine is a robust and efficient casting solution that meets the diverse needs of modern manufacturing. With its precise casting abilities, ease of operation, and cost-effectiveness, this machine offers a competitive edge to foundries looking to streamline their production processes and improve the quality of their cast products.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch