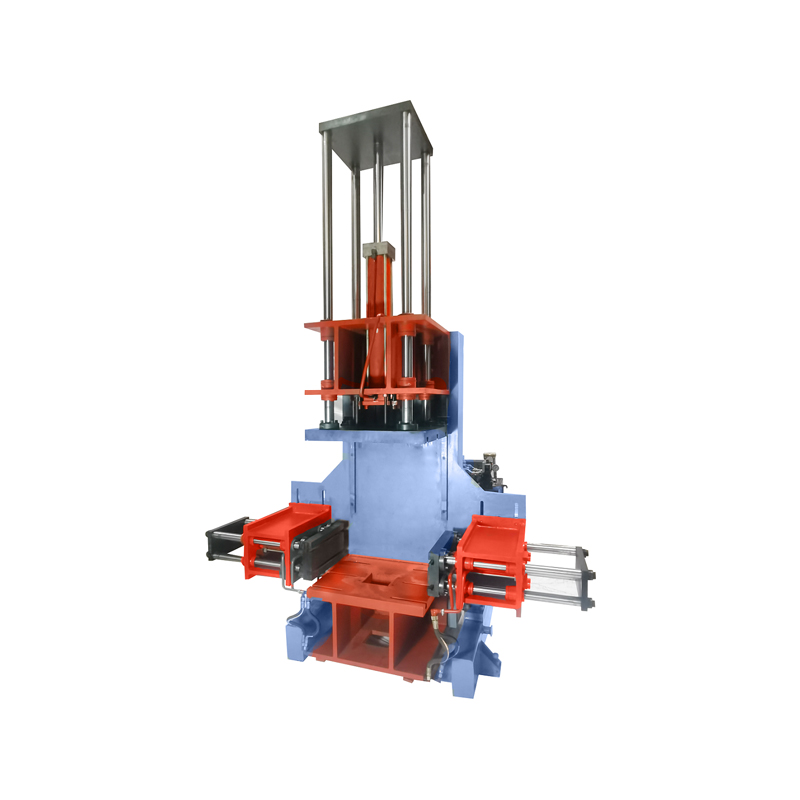

Gravity Casting Machine

HZ860-4D Tiltable Gravity Casting Machine

A Tiltable Gravity Casting Machine is a vital piece of equipment in the manufacturing of high-precision metal castings. Designed for versatility and precision, this machine provides a reliable solution for a wide range of casting applications, particularly in industries such as automotive, aerospace, and heavy machinery.

Key Features and Advantages

One of the primary advantages of the Tiltable Gravity Casting Machine is its ability to provide consistent and uniform metal flow. This design ensures that molten metal fills the mold evenly, A significant reduction the risks of air pockets or other defects that can compromise casting quality. The tilting mechanism allows the operator to adjust the angle of the mold, providing better control over the metal's movement.

In addition to its precision, the Tiltable Gravity Casting Machine offers improved energy efficiency. The casting process is designed to optimize the use of molten metal, reducing waste and A significant reduction the need for additional reprocessing. This not only lowers operational costs but also enhances overall production speed, enabling manufacturers to meet tighter deadlines and improve their output.

Flexibility and Adaptability

Another significant benefit of the Tiltable Gravity Casting Machine is its adaptability to a variety of metals and alloys. Whether you’re working with aluminum, copper, magnesium, or other non-ferrous metals, this machine can handle a wide range of materials. This versatility makes it ideal choice for manufacturers who need to produce castings from different metal types without investing in multiple machines.

Enhanced Durability and Maintenance

The design of the Tiltable Gravity Casting Machine also contributes to its durability. Built with high-quality materials and engineered for long-lasting performance, this machine is resistant to wear and tear. Regular maintenance is straightforward, ensuring Very small downtime during operations. The robust construction of the machine also ensures that it remains operational in demanding industrial environments, making it a dependable choice for continuous casting operations.

Improved Safety and Control

Safety is a priority in any industrial setting, and the Tiltable Gravity Casting Machine is equipped with features to protect both the operator and the equipment. Advanced control systems allow for precise monitoring of the casting process, ensuring that molten metal is handled safely and efficiently. The machine also includes automated features that reduce the need for manual intervention, further reducing the risk of accidents and errors during production.

The Tiltable Gravity Casting Machine is a powerful and versatile solution for manufacturers looking to enhance their casting operations. With its precise control, energy efficiency, and adaptability to a variety of metals, it is ideal choice for producing high-quality castings.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch