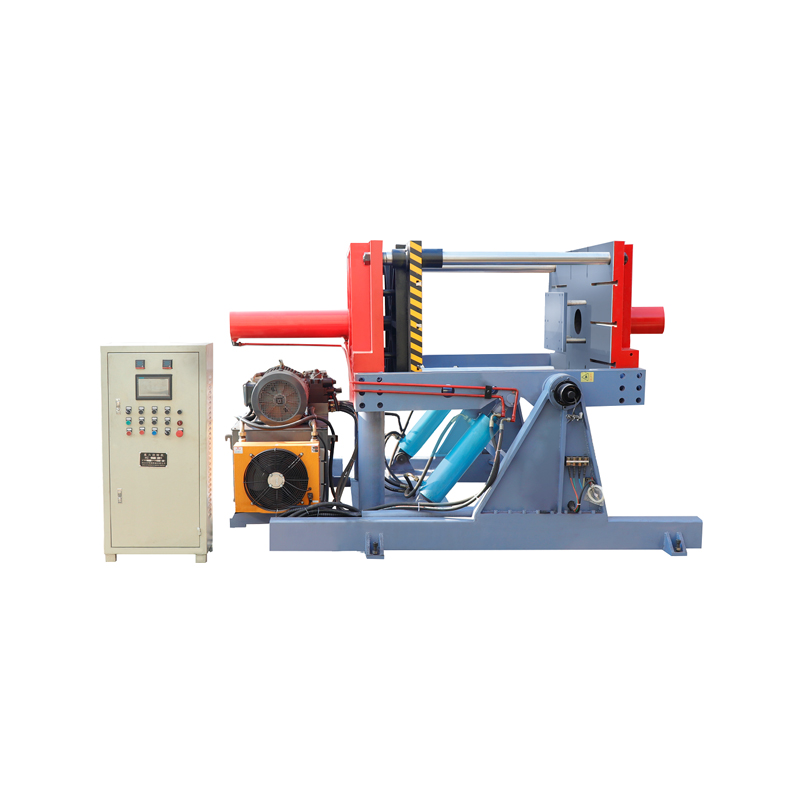

Gravity Casting Machine

NZJ1280Q Gravity Casting Machine With Strong Material Adaptability

The Gravity Casting Machine is a versatile and efficient solution for industries requiring high-quality metal castings. Known for its adaptability to a wide range of materials, this casting machine excels in producing parts that meet precise specifications with outstanding consistency.

Key Features

Material Versatility

One of the protrude features of the Gravity Casting Machine is its strong material adaptability. It is designed to work with a variety of metals, including aluminum, zinc, copper alloys, and other non-ferrous metals. This broad material compatibility allows manufacturers to produce castings with different properties, catering to industries such as automotive, aerospace, and general manufacturing. The machine’s flexibility ensures that it can accommodate both high-volume production runs and custom, small-batch needs.

Precise Control Over Casting Process

The Gravity Casting Machine is equipped with advanced control systems that ensure precise management of the pouring process. This helps minimize defects such as air pockets, shrinkage, and cold shuts, which can affect the final quality of the casting. By maintaining good pouring conditions, the machine delivers consistent results, reducing the need for rework or scrap material, thereby increasing overall efficiency.

Energy Efficiency

The Gravity Casting Machine is designed with energy efficiency in mind. Compared to other casting technologies, gravity casting uses a lower amount of energy because it relies on gravity to fill the mold. This not only lowers operational costs but also reduces the carbon footprint of the manufacturing process. This makes it a cost-effective and environmentally friendly solution for industries looking to optimize both their production costs and sustainability efforts.

High Casting Strength and Durability

Due to the method in which the molten metal is poured into the mold, castings produced by the Gravity Casting Machine typically exhibit better strength and durability. The casting process ensures a denser, more uniform material structure, which is crucial for parts that require high mechanical performance. This makes the machine particularly suitable for producing components that undergo rigorous wear and tear, such as engine parts, gears, and structural components.

Faster Production Times

The Gravity Casting Machine enables faster production times, thanks to its efficient casting process and high cycle speeds. By using gravity to fill the mold, the machine can reduce the time required for each casting, increasing overall throughput. This makes it ideal for industries where time-to-market is critical and fast production runs are essential to meeting demand.

With its strong material adaptability, precise control, energy efficiency, and fast production capabilities, the Gravity Casting Machine is a key asset for manufacturers looking to improve the quality and consistency of their castings. Whether you’re working with aluminum, zinc, or copper alloys, this casting machine ensures good results for a wide range of applications. Its robust design and efficiency make it a go choice for industries demanding precision, durability, and cost-effectiveness.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch