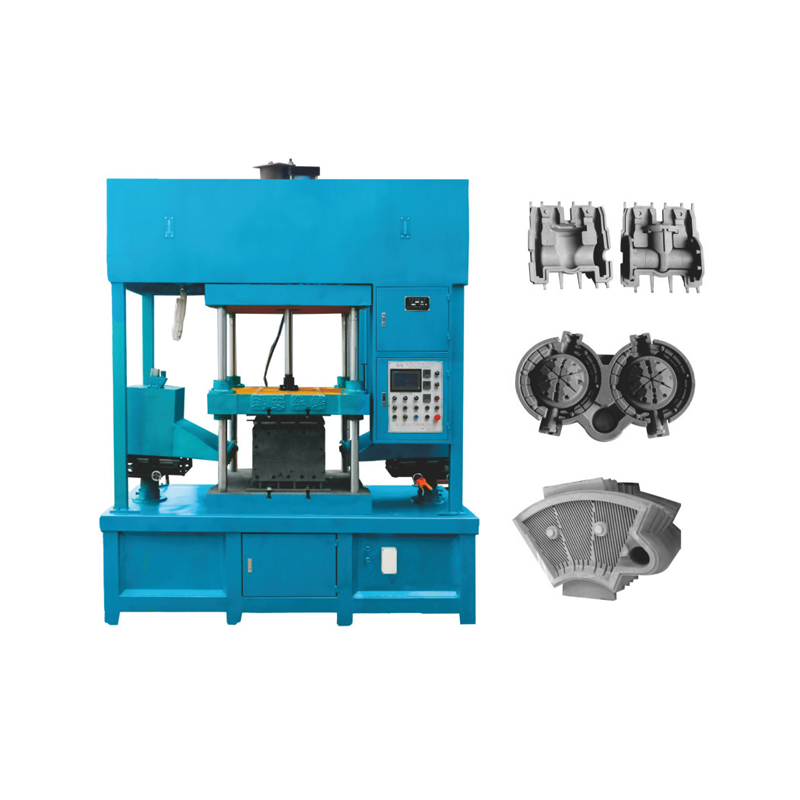

Horizontal Parting Core Shooting Machine

HZ800-C Fully Automatic Core Shooting Machine With Core Pulling

The fully automatic core shooting machine with core pulling is designed to meet the growing demands of industries requiring efficient, high-precision core production. This advanced machine integrates front-end technology to provide consistent results, high productivity, and a user-friendly experience. It is ideal for various applications, particularly in metal casting and molding industries, where precision and reliability are essential.

Key Features of the Fully Automatic Core Shooting Machine

One of the protrude features of the fully automatic core shooting machine with core pulling is its automatic operation. This feature reduces human intervention, ensuring a more consistent and error-free production process. The machine operates efficiently with Very small downtime, The largest output while maintaining high standards of quality.

The integration of core pulling into the system further improves the overall process. The automatic core pulling mechanism ensures that the cores are extracted from molds quickly and accurately, preventing damage to the cores and molds. This significantly reduces the time spent on manual labor and ensures that production can continue without interruptions.

Enhanced Precision and Consistency

Precision is crucial in industries that rely on molds and cores for production. The fully automatic core shooting machine with core pulling guarantees high precision in core formation. The machine’s advanced control systems and precise timing mechanisms enable it to produce consistent cores with Very small variation. This leads to higher-quality products, fewer defects, and less waste.

The core shooting machine is equipped with a range of sensors and monitoring tools that ensure the entire production process runs smoothly. These sensors monitor the pressure, temperature, and other critical variables, making adjustments as necessary to maintain good conditions for core shooting and core pulling.

User-Friendly Interface and Automation

The intuitive interface of the fully automatic core shooting machine with core pulling makes it easy for operators to manage and adjust settings as needed. The machine’s automated features reduce the need for manual adjustments, which As small as possible the chances of human error and improves operational efficiency. Operators can quickly monitor the system’s status and make adjustments using the touch screen or control panel.

With automation at its core, this core shooting machine eliminates the need for manual labor during the core shooting and pulling stages. This reduces the risk of repetitive strain injuries and As small as possible the cost of labor. Additionally, the system’s automated features help reduce the chance of errors, ensuring that every core meets the specified quality standards.

Reliability and Durability

Durability is another key factor when considering the fully automatic core shooting machine with core pulling. Built with high-quality materials and designed for long-term use, this machine requires Very small maintenance. Its robust construction ensures it can withstand the rigors of continuous operation, providing reliable performance over an extended period.

Applications Across Multiple Industries

The fully automatic core shooting machine with core pulling is complete for industries that require high-precision mold and core production. It is commonly used in metal casting, automotive manufacturing, and the production of complex industrial parts. This machine’s ability to handle high volumes of core production while maintaining outstanding quality makes it an invaluable asset to these industries.

he fully automatic core shooting machine with core pulling is a powerful and efficient solution for businesses looking to optimize their core production processes. Its advanced features, including automatic core pulling, precision control, and ease of use, make it an essential tool for any high-volume manufacturing environment.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch