Gravity Casting Machine Supplier

-

NZJ640Q Controllable Gravity Casting Machine

The Controllable Gravity Casting Machine is designed to meet the growing demands of precision castin... -

NZJ750Q Heat-Resistant Durable Gravity Casting Machine

The Heat-resistant durable gravity casting machine is a advanced solution for precision casting in v... -

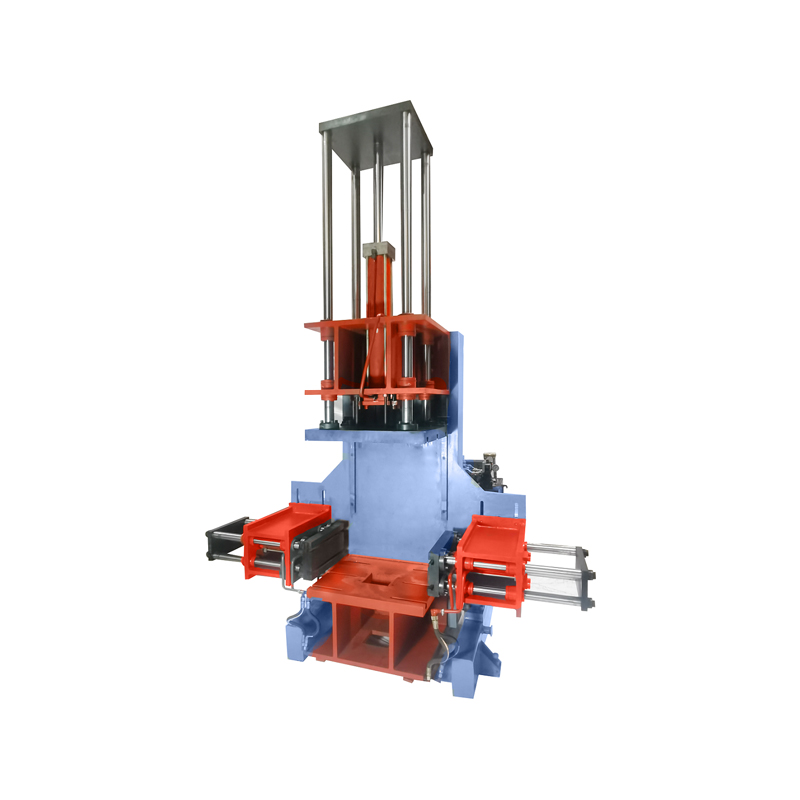

NZJ860Q Large Platform Gravity Casting Machine

The Large Platform Gravity Casting Machine is designed to meet the needs of industries requiring pre... -

NZJ960Q Stable Utilization Rate High Gravity Casting Machine

The Stable Utilization Rate High Gravity Casting Machine is designed to meet the demands of industri... -

NZJ1080Q High Precision Easy Operation Gravity Casting Machine

The High Precision Easy Operation Gravity Casting Machine is designed to streamline the casting proc... -

NZJ1280Q Gravity Casting Machine With Strong Material Adaptability

The Gravity Casting Machine is a versatile and efficient solution for industries requiring high-qual... -

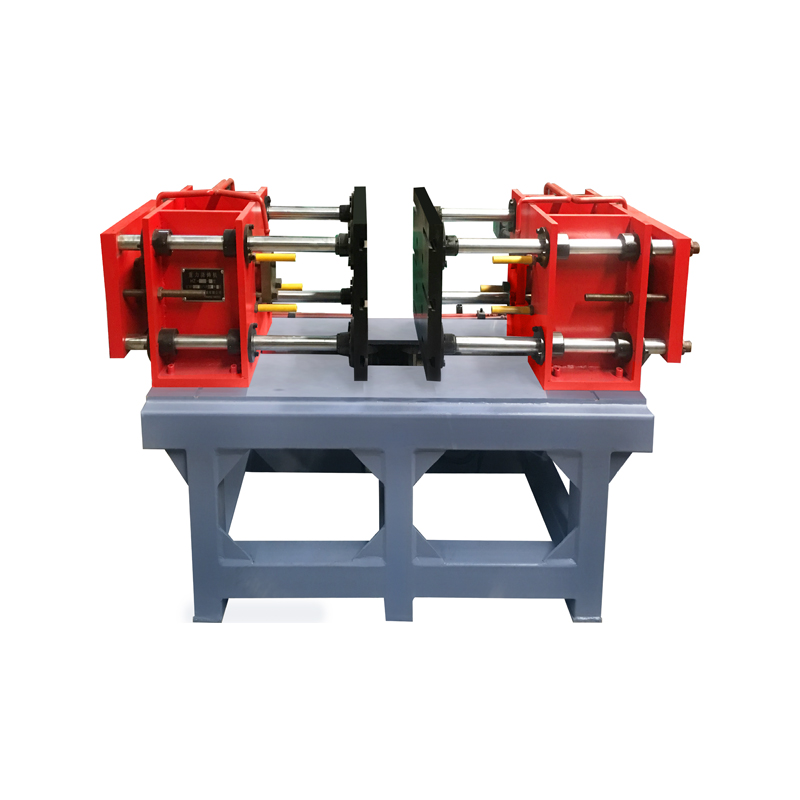

HZ650-2D Horizontal Parting Gravity Casting Machine

The Horizontal Parting Gravity Casting Machine is an essential tool in the foundry industry, designe... -

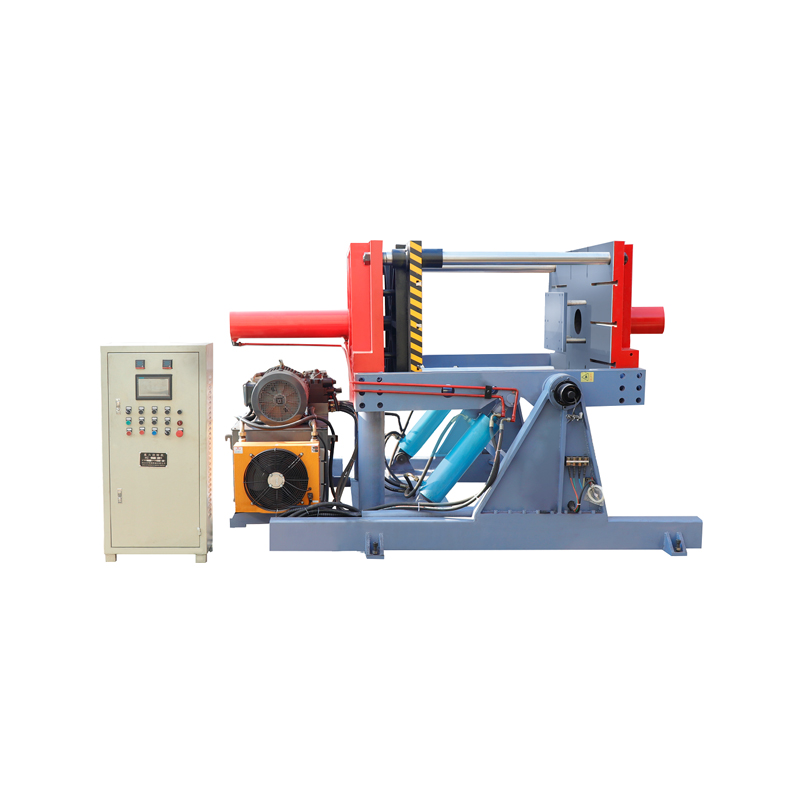

HZ860-4D Tiltable Gravity Casting Machine

A Tiltable Gravity Casting Machine is a vital piece of equipment in the manufacturing of high-precis...

A Gravity Casting Machine is a key piece of equipment designed for producing high-quality castings through the use of gravity to pour molten metal into molds. This process ensures precision, cost-effectiveness, and versatility, making it ideal choice for manufacturers across various industries.

Key Features of the Gravity Casting Machine

High Precision Casting

The Gravity Casting Machine provides Individual cases control over the pouring process, which directly impacts the quality of the final casting. By utilizing gravity to fill the mold, the machine achieves even distribution of molten metal, reducing the chances of defects and enhancing the accuracy of the final product.

Cost-Effective Production

One of the protrude advantages of the Gravity Casting Machine is its ability to lower production costs. The gravity-based process does not require excessive energy consumption or complex mechanisms, which results in a more affordable casting process compared to other methods. This makes it ideal choice for businesses looking to balance quality with budget efficiency.

Versatility in Material Use

Whether you're working with aluminum, zinc, or other non-ferrous metals, the Gravity Casting Machine can handle a wide range of materials. Its adaptability makes it suitable for casting various parts and components, from small intricate pieces to larger industrial parts, ensuring its place in many different industries.

Durability and Longevity

The Gravity Casting Machine is built with robust materials and designed for long-term use. It requires Very small maintenance, making it a reliable and durable option for continuous operations. The machine's high resistance to wear and tear helps reduce downtime, improving overall productivity.

Advantages of Using the Gravity Casting Machine

Efficient Production: The simple yet effective process used by the Gravity Casting Machine leads to faster cycle times and higher throughput.

Enhanced Surface Finish: Parts produced using the Gravity Casting Machine often have better surface finishes, which may require less post-casting treatment.

Reduced Porosity: The gravity-driven process As small as possible the risk of air pockets and porosity within the casting, resulting in stronger, more reliable components.

Applications of the Gravity Casting Machine

The Gravity Casting Machine is ideal for producing a wide range of parts, from automotive components to industrial machinery. Its applications extend to the production of both high-precision parts and large-scale items, making it an essential machine in industries such as aerospace, automotive, and general manufacturing.

Gravity Casting Machine offers numerous benefits, including precise casting, cost efficiency, and versatility. Its durability, ease of operation, and wide application range make it a valuable asset for any manufacturing process that requires high-quality metal parts.

About Us

Honor

News

-

Industry News 2026-02-20

The Evolving Performance of Stainless Steel Castings Stainless steel castings have long been a cornerstone of demanding industrial applications, prize...

View More -

Industry News 2026-02-13

What Is Coated Sand Casting Mold and How Does It Work? Coated sand casting mold refers to a sand mold that has been coated with a refractory or bindin...

View More -

Industry News 2026-02-06

Valve fittings castings are a core component in fluid control systems across many industries. They are manufactured through casting processes such as ...

View More -

Industry News 2026-01-28

Engineering machinery castings are metal components formed by pouring molten metal into a mold cavity that holds the shape of a required part. This ma...

View More

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch