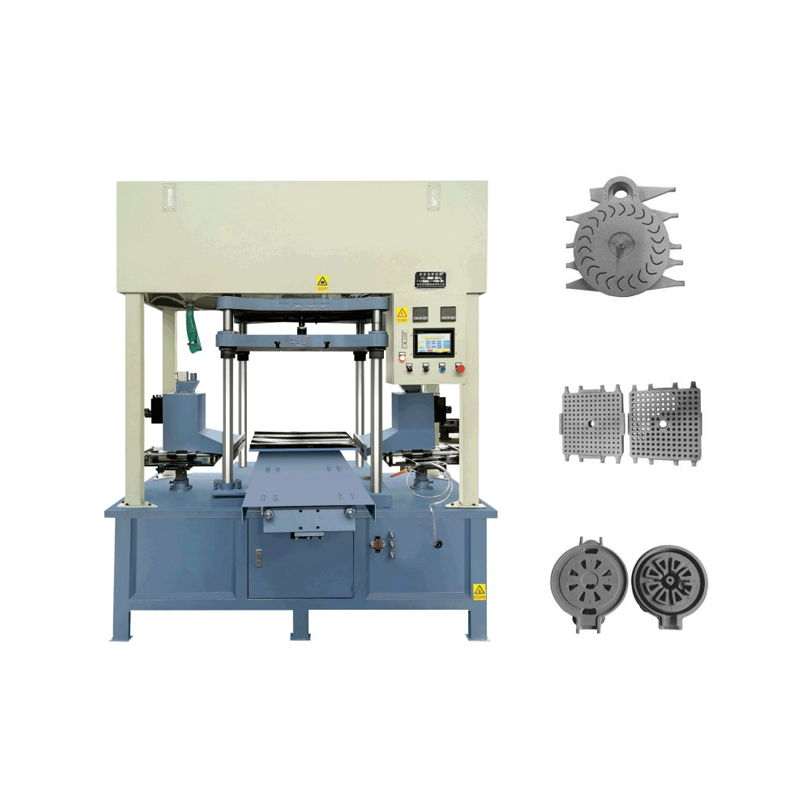

Horizontal Parting Core Shooting Machine

HZ750-S Upper Mold Automatic Shell Core Shooting Machine

The Upper Mold Automatic Shell Core Shooting Machine is an advanced solution designed for precision molding in the manufacturing industry. It is particularly suitable for industries such as automotive, aerospace, and heavy machinery, where high-quality castings are essential. This machine is engineered to provide efficient shell core production, ensuring reduced cycle times, consistent output, and better mold quality.

Enhanced Efficiency and Speed

One of the protrude features of the Upper Mold Automatic Shell Core Shooting Machine is its ability to operate with high efficiency. By automating the shell core shooting process, the machine As small as possible human intervention, reducing the chances of error and ensuring faster production cycles. This automation not only speeds up the overall process but also improves throughput, enabling manufacturers to meet tight production deadlines without compromising quality.

Precise Control for Consistent Results

The Upper Mold Automatic Shell Core Shooting Machine provides Individual cases control over the entire molding process. Through its sophisticated control system, the machine ensures that each mold receives the exact amount of material required, which results in a consistent shell core formation. This precise control eliminates variability, ensuring that the final product maintains high standards of quality, meeting both customer and regulatory requirements.

High-Quality Materials and Durability

Built with high-quality materials, the Upper Mold Automatic Shell Core Shooting Machine is designed for longevity. The durable components of the machine can withstand the rigors of continuous operation, making it a reliable investment for businesses looking for long-term solutions.

Flexible Production Capabilities

The Upper Mold Automatic Shell Core Shooting Machine is versatile in its ability to work with a range of materials. Whether working with sand, resins, or other composite materials, this machine can produce complex shell core designs with ease. This flexibility allows manufacturers to customize their products according to specific requirements, providing greater design freedom and increasing overall production capability.

User-Friendly Interface

The Upper Mold Automatic Shell Core Shooting Machine is designed with an intuitive interface, making it easy for operators to set up and manage production runs. With simple controls and clear readouts, the machine As small as possible the learning curve for new operators and reduces the need for constant supervision.

Reduced Waste and Environmental Impact

Another significant advantage of the Upper Mold Automatic Shell Core Shooting Machine is its ability to minimize material waste. Through accurate material handling and precise molding techniques, the machine ensures that only the necessary amount of material is used. This results in reduced scrap and lower material costs.

Easy Maintenance and Support

Maintaining the Upper Mold Automatic Shell Core Shooting Machine is straightforward, thanks to its simple design and easily accessible parts. Regular maintenance is essential to keep the machine running at peak performance, and the machine's user-friendly design makes this process hassle-free. Additionally, manufacturers can rely on comprehensive customer support to ensure any issues are addressed promptly.

The Upper Mold Automatic Shell Core Shooting Machine offers a wide array of benefits that improve production efficiency, product quality, and overall operational costs. By providing precise control, reducing material waste, and offering flexible production capabilities, this machine is a valuable asset for any manufacturing facility.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch