Metal Casting Molds Company

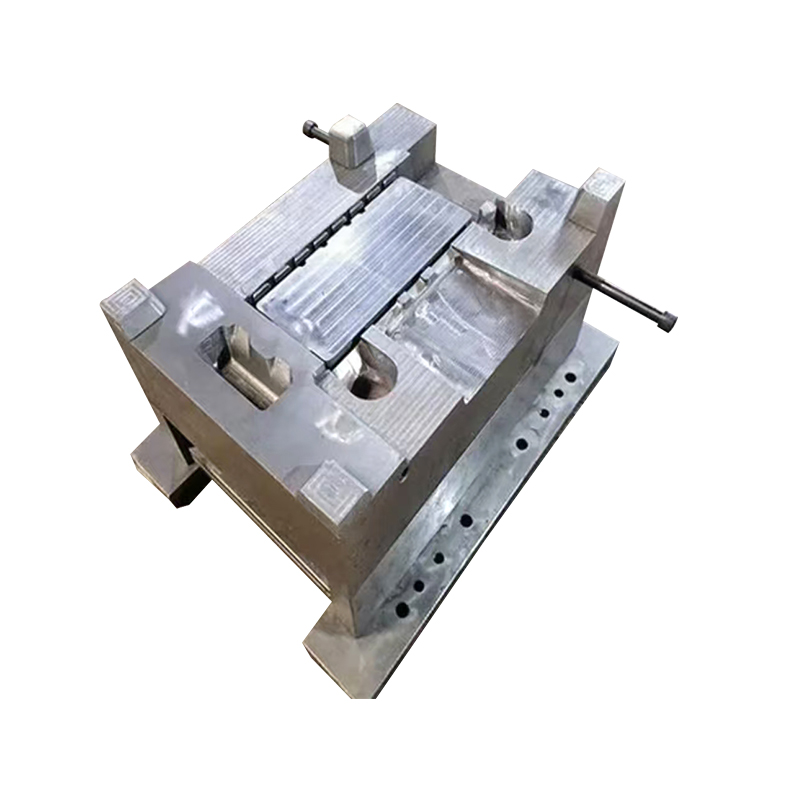

Metal casting molds are essential tools in the manufacturing process, designed to provide precise, consistent results for a variety of metalworking applications. Whether you are producing small components or large industrial parts, the quality of the mold plays a crucial role in achieving the desired outcome.

Key Features of Metal Casting Molds

1. High-Quality Materials

Our metal casting molds are made from high-grade materials that ensure durability and long-lasting performance. These molds can withstand the high temperatures and pressures involved in the casting process without compromising structural integrity.

2. Precision Engineering

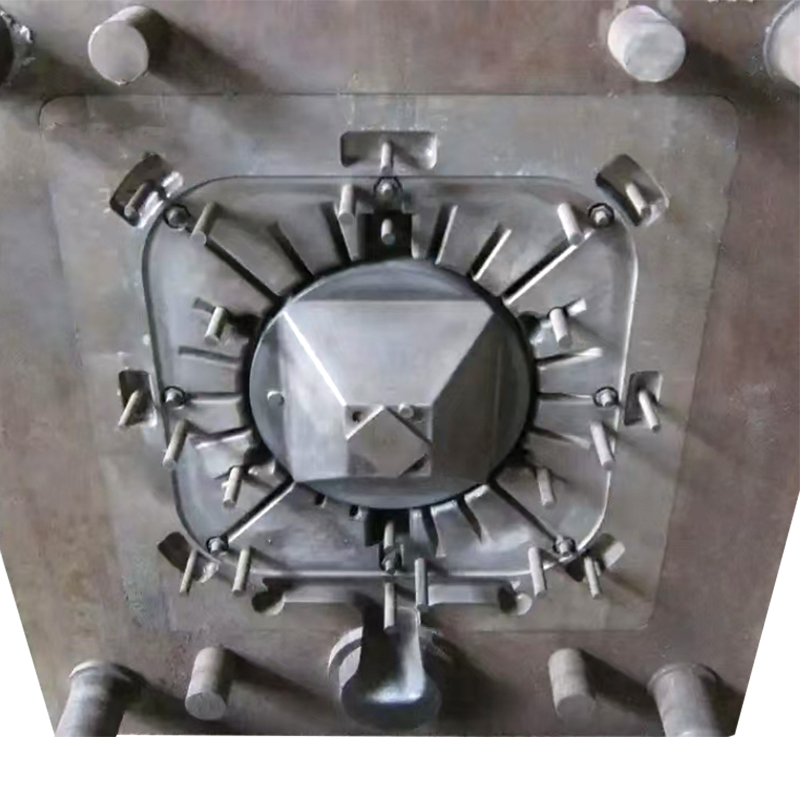

Each metal casting mold is designed with meticulous attention to detail, ensuring that every cast is produced with accuracy.

3. Versatility in Application

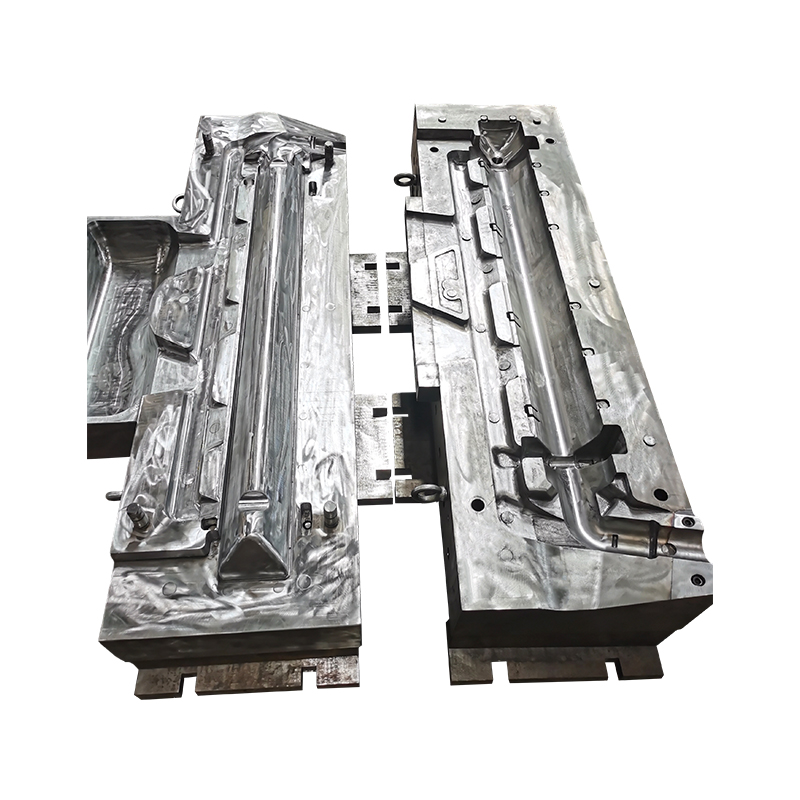

These molds are suitable for a wide range of casting metals, including aluminum, bronze, copper, and steel. This versatility makes them an outstanding choice for industries such as automotive and heavy machinery, where high-quality parts are essential.

4. Enhanced Heat Resistance

Our molds are specifically designed to handle special heat. The better heat resistance ensures that the molds maintain their shape and integrity, even when exposed to high temperatures during the casting process.

Applications of Metal Casting Molds

The versatility of metal casting molds allows them to be used in a variety of industries. From precision components in the automotive sector to complex parts in aerospace applications, these molds play a critical role in producing high-quality castings. They are ideal for both mass production and custom orders, offering flexibility for a range of production volumes.

When it comes to metal casting molds, quality and precision are . Our molds are engineered to ensure a seamless casting process that results in high-performance, durable parts. The combination of advanced material technology, precision design, and customization options makes our molds a reliable choice for any casting project.

Whether you are working with small-scale projects or large industrial productions, our metal casting molds offer the reliability and performance you need. With a focus on quality, durability, and precision, these molds are designed to meet highest standards in the metal casting industry.

About Us

Honor

News

-

Industry News 2026-02-13

What Is Coated Sand Casting Mold and How Does It Work? Coated sand casting mold refers to a sand mold that has been coated with a refractory or bindin...

View More -

Industry News 2026-02-06

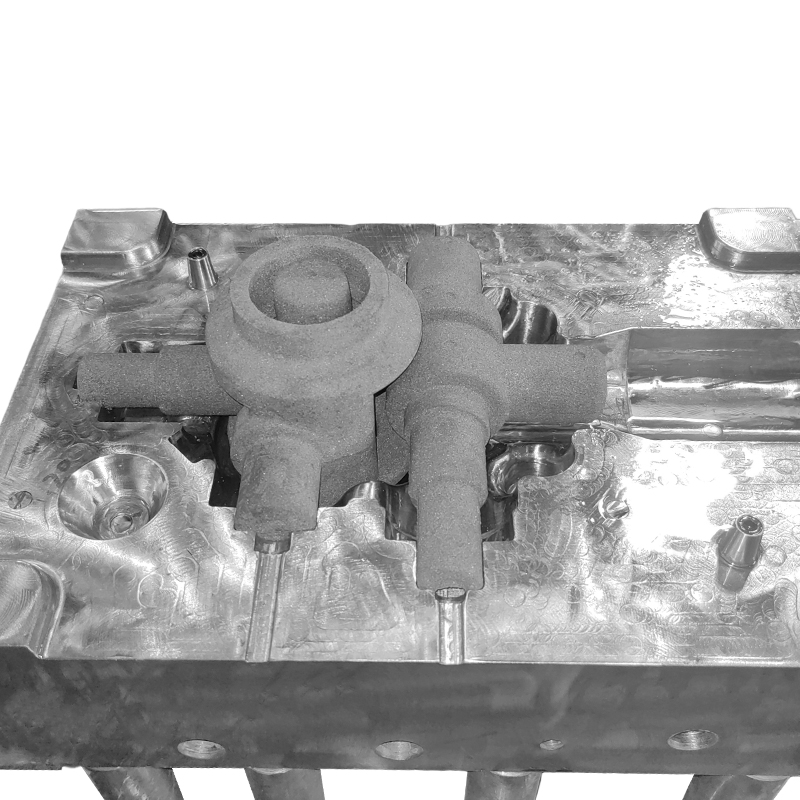

Valve fittings castings are a core component in fluid control systems across many industries. They are manufactured through casting processes such as ...

View More -

Industry News 2026-01-28

Engineering machinery castings are metal components formed by pouring molten metal into a mold cavity that holds the shape of a required part. This ma...

View More -

Industry News 2026-01-23

Mechanical parts castings are fundamental components in the manufacturing of various products used in industries such as automotive, aerospace, machin...

View More

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch