Vertical Parting Core Shooting Machine Factory

-

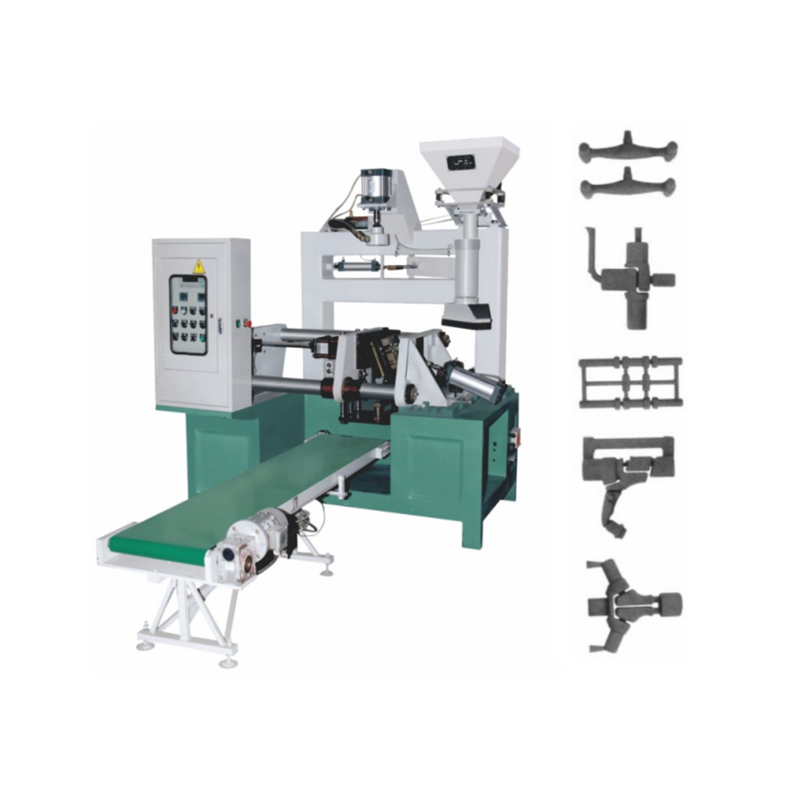

HZ9404 Small Size Vertical Parting Core Shooting Machine

The Small Size Vertical Parting Core Shooting Machine is a compact and efficient solution designed f... -

HZ9405 Double-Action Mold Vertical Parting Core Shooting Machine

The Double-action Mold Vertical Parting Core Shooting Machine is an advanced and efficient solution ... -

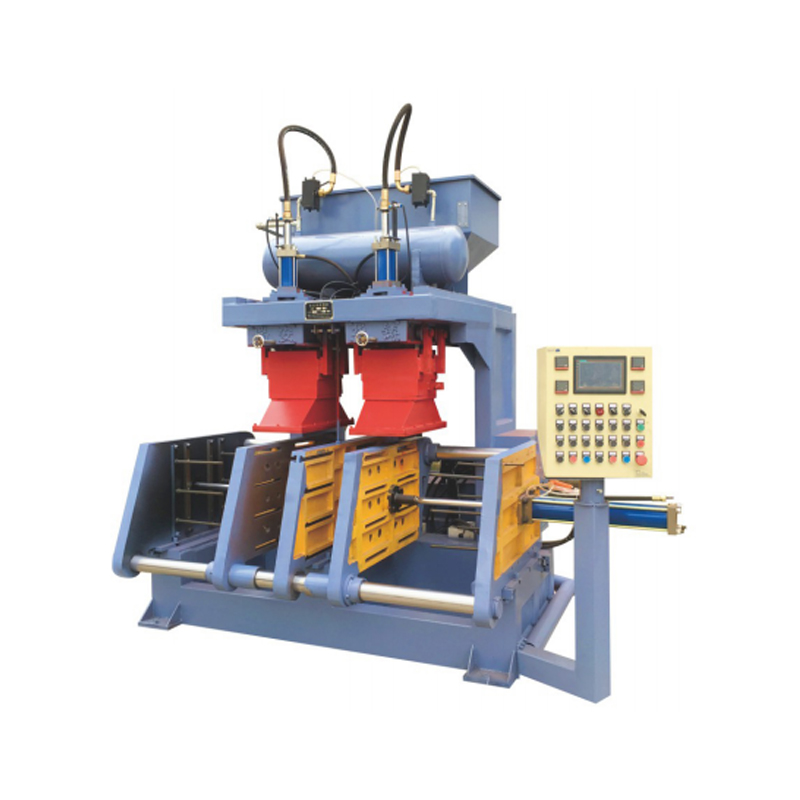

HZ9406 Double Station Vertical Parting Core Shooting Machine

The Double Station Vertical Parting Core Shooting Machine is a advanced equipment designed to meet t... -

HZ9407 Double Station Vertical Parting Core Shooting Machine With Movable Mold Flipping Up

The Double Station Vertical Parting Core Shooting Machine with Movable Mold Flipping Up is a versati... -

HZ9408 Standard Vertical Parting Core Shooting Machine

The Standard Vertical Parting Core Shooting Machine is an essential piece of equipment designed for ... -

HZ361 Fully Automatic Vertical Parting Core Shooting Machine

The Double Station Vertical Parting Core Shooting Machine with Movable Mold Flipping Up is a versati...

The Vertical Parting Core Shooting Machine is a versatile and efficient solution designed to meet the high demands of modern foundry production. With its vertical parting structure and advanced automation features, this machine offers outstanding adaptability and consistent performance in producing high-quality sand cores. It is widely used for both hot box and cold box processes, making it suitable for a wide range of casting applications.

Key Features

Vertical Parting Structure

The Vertical Parting Core Shooting Machine adopts a vertical mold opening and closing mechanism, which operates perpendicularly to the ground. This design is particularly beneficial for producing taller sand cores, providing a stable and compact footprint suitable for various workshop environments.

High Precision Operation

Equipped with precision-guided sliding mold systems, the Vertical Parting Core Shooting Machine ensures smooth and accurate movements. The high positioning accuracy contributes to consistent dimensional tolerances, which is essential for producing complex and high-precision sand cores.

Advanced Automation

Automation is at the core of the Vertical Parting Core Shooting Machine. The machine supports automatic sand shooting, core curing, mold opening, and core ejection. These automated processes reduce manual labor and significantly enhance production efficiency while A significant reduction operational errors.

Dual-Process Compatibility

Designed for flexibility, the Vertical Parting Core Shooting Machine is compatible with both hot core box and cold core box technologies. It can efficiently produce various shapes and sizes of sand cores, meeting diverse foundry requirements.

Energy-Saving Design

The machine offers multiple heating options to suit different production needs. In addition, the sand shooting head automatically returns to the sand filling position after core shooting, reducing the risk of sand clogging and promoting material efficiency.

Multi-Station Capability

Selected models of the Vertical Parting Core Shooting Machine can be configured with two or more mold sets, enabling dual or multi-station operation. This feature significantly boosts production output and maximizes equipment utilization.

Application and Advantages

Thanks to its reliable performance and adaptable design, the Vertical Parting Core Shooting Machine is widely used in the foundry industry for producing complex and accurate sand cores. It is especially suitable for the mass production of small to medium-sized castings with intricate shapes and precise dimensional requirements.

Whether it's improving productivity, enhancing core quality, or ensuring operational stability, the Vertical Parting Core Shooting Machine offers a balanced solution for foundries seeking consistency and efficiency. With more than ten references to its name, the Vertical Parting Core Shooting Machine remains a trusted choice in the core-making process.

About Us

Honor

News

-

Industry News 2026-02-13

What Is Coated Sand Casting Mold and How Does It Work? Coated sand casting mold refers to a sand mold that has been coated with a refractory or bindin...

View More -

Industry News 2026-02-06

Valve fittings castings are a core component in fluid control systems across many industries. They are manufactured through casting processes such as ...

View More -

Industry News 2026-01-28

Engineering machinery castings are metal components formed by pouring molten metal into a mold cavity that holds the shape of a required part. This ma...

View More -

Industry News 2026-01-23

Mechanical parts castings are fundamental components in the manufacturing of various products used in industries such as automotive, aerospace, machin...

View More

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch