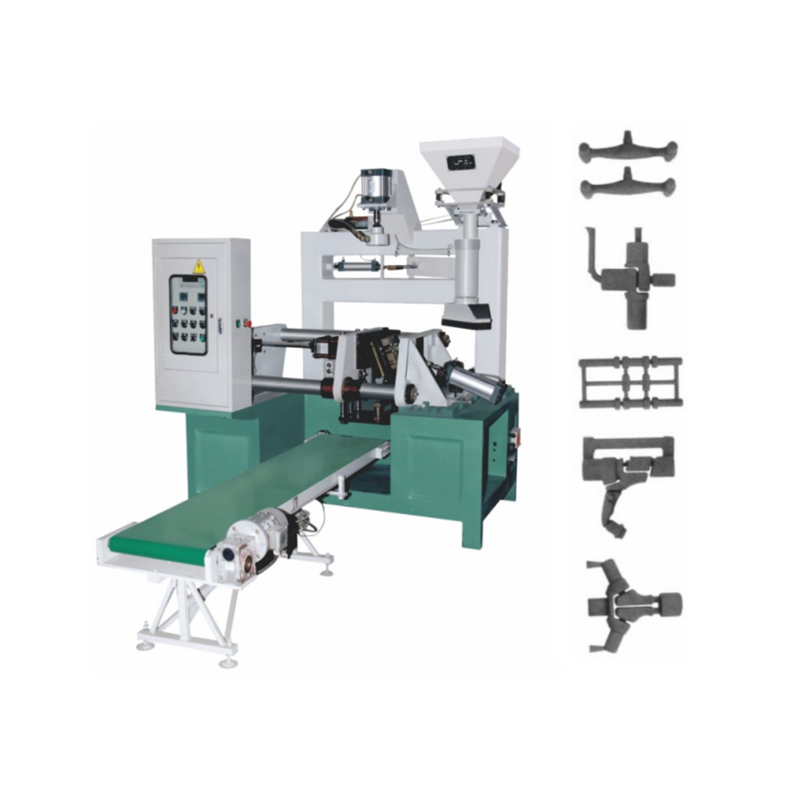

The Core Shooting Machine is an essential piece of equipment in modern foundry operations. It plays a crucial role in the efficient and precise production of sand cores, which are fundamental in the casting process. Designed to meet the growing demands of the casting industry, the Core Shooting Machine combines advanced technology with reliable performance, making it a valuable asset in any production line.

Key Features

1. High Production Efficiency

The Core Shooting Machine is engineered to produce high-quality sand cores at a rapid pace. Its efficient cycle time significantly reduces production periods, enabling foundries to meet tight schedules and increase output without compromising quality.

2. Precision Control

One of the protrude characteristics of the Core Shooting Machine is its ability to precisely control the dimensions and shapes of sand cores. This precision ensures that castings meet strict dimensional requirements, enhancing the overall quality of the final product.

3. Strong Adaptability

Designed to handle a wide variety of complex core shapes, the Core Shooting Machine offers outstanding adaptability. It can be customized for various casting applications, making it suitable for diverse production needs across industries.

4. High Degree of Automation

The Core Shooting Machine As small as possible the need for manual labor through its advanced automation features. This not only reduces physical workload but also enhances operational stability and repeatability, ensuring consistent output.

Applications

The Core Shooting Machine is widely utilized in the foundry sector, especially in automotive manufacturing. For example, in the production of engine blocks, cylinder heads, and intake and exhaust manifolds, the Core Shooting Machine ensures the creation of high-precision sand cores. This guarantees the dimensional accuracy and surface quality required for critical automotive components.

Advantages

The use of a Core Shooting Machine brings several key advantages:

Enhanced production efficiency through faster cycle times

Improved casting accuracy and surface finish

Reduced labor intensity and operational errors

Versatility in producing complex core geometries

Lower overall production costs

These benefits make the Core Shooting Machine a valuable investment for foundries aiming to improve productivity and product consistency.

With its blend of efficiency, precision, and adaptability, the Core Shooting Machine is a cornerstone in the evolution of modern casting technology. Its ability to meet the demands of complex and high-volume production environments underscores its importance in today’s competitive manufacturing landscape. Whether for small workshops or large-scale industrial operations, the Core Shooting Machine continues to deliver reliable performance and operational value.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch