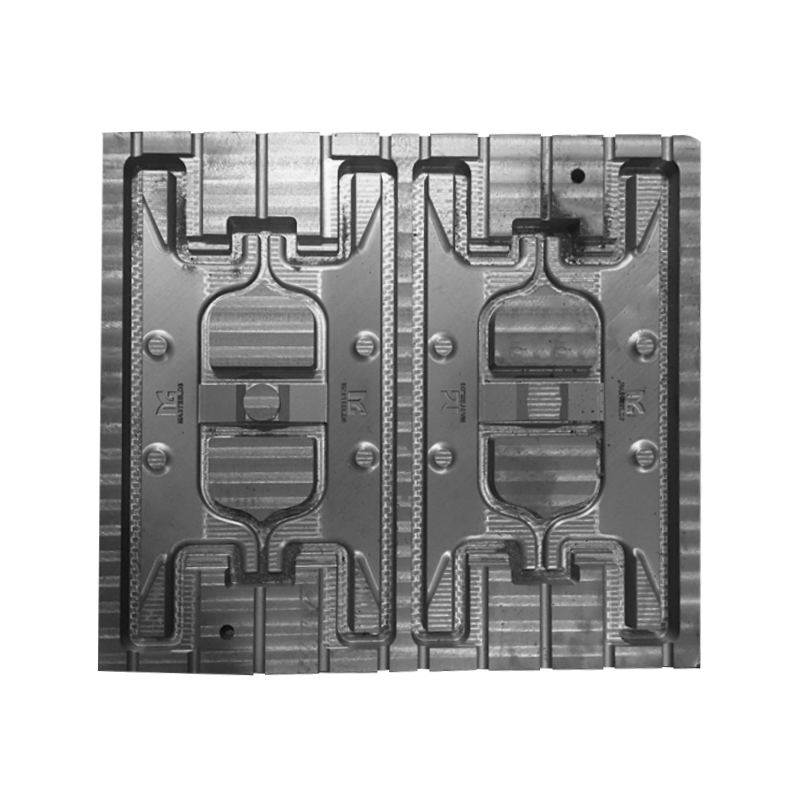

Automobile Castings Manufacturer

Automotive casting parts are essential components used in the manufacturing of various automotive systems, including engines, transmissions, and chassis. These parts are designed to provide both strength and durability, ensuring the safe and efficient operation of vehicles. Made from a variety of metals, automotive casting parts are produced through a casting process that allows for intricate designs and high precision.

High Precision and Complex Design

One of the main advantages of automotive casting parts is their ability to accommodate complex shapes and intricate details. The casting process enables manufacturers to create parts with precise dimensions, ensuring that each part fits seamlessly into the vehicle's overall design.

Cost-Effective Production

Casting automotive parts is often more cost-effective compared to other manufacturing methods, such as machining or forging. The casting process allows for the mass production of parts, reducing the need for expensive tooling and labor costs. By using automotive casting parts, manufacturers can maintain quality while keeping production costs lower, which benefits both the manufacturer and the consumer.

better Strength and Durability

Automotive casting parts are known for their high strength and durability. The casting process enables the creation of parts that can withstand the harsh conditions found in the automotive environment. From special temperatures to vibrations and mechanical stress, these parts are designed to perform reliably over time, offering outstanding resistance to wear and tear. This durability ensures that automotive casting parts contribute to the longevity of vehicles and their key systems.

Versatility in Materials

Automotive casting parts can be made from a variety of materials, including aluminum, steel, and iron. Each material offers its own set of advantages, such as lightweight aluminum for better fuel efficiency or cast iron for strength and heat resistance. The ability to select the ideal material for specific automotive applications further enhances the versatility of automotive casting parts, allowing for better performance across different vehicle types and functions.

Improved Safety and Reliability

When it comes to automotive components, safety and reliability are . Automotive casting parts undergo strict quality control procedures to ensure that they meet industry standards for strength, precision, and performance. By using these high-quality casting parts, vehicle manufacturers can produce cars and trucks that are both safe and reliable, finallyly contributing to the overall safety of drivers and passengers.

Automotive casting parts offer a combination of precision, durability, and cost-effectiveness that makes them ideal choice for a wide range of automotive applications. Whether it’s for enhancing vehicle performance or ensuring long-term reliability, these parts play a crucial role in the automotive industry. By choosing automotive casting parts, manufacturers can produce high-quality vehicles that meet the demands of modern consumers.

About Us

Honor

News

-

Industry News 2026-02-13

What Is Coated Sand Casting Mold and How Does It Work? Coated sand casting mold refers to a sand mold that has been coated with a refractory or bindin...

View More -

Industry News 2026-02-06

Valve fittings castings are a core component in fluid control systems across many industries. They are manufactured through casting processes such as ...

View More -

Industry News 2026-01-28

Engineering machinery castings are metal components formed by pouring molten metal into a mold cavity that holds the shape of a required part. This ma...

View More -

Industry News 2026-01-23

Mechanical parts castings are fundamental components in the manufacturing of various products used in industries such as automotive, aerospace, machin...

View More

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch