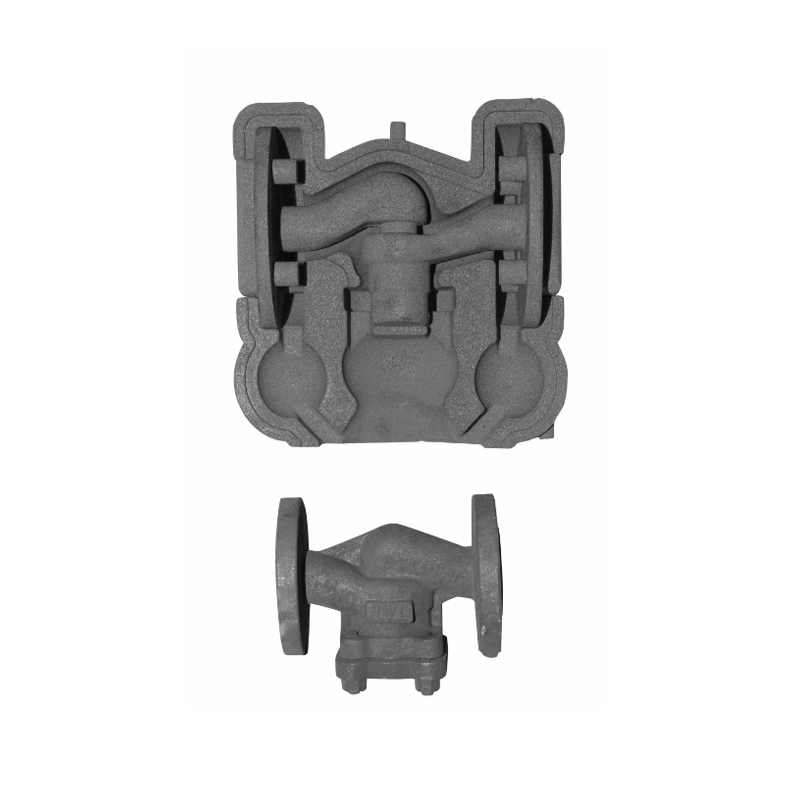

Coated Sand Casting Mold Factory

Coated sand casting molds are a crucial element in modern casting processes, providing a highly effective solution for producing complex and precise metal parts. These molds are designed to deliver outstanding surface finishes and dimensional accuracy, making them ideal for a wide range of industries, from automotive to aerospace.

High Precision and Accuracy

One of the protrude features of coated sand casting molds is their ability to produce high-precision components. The coating layer applied to the sand ensures that the mold surface is smooth, which helps to achieve a high-quality finish on the final product. This enhanced precision As small as possible defects and reduces the need for post-processing, saving time and costs.

better Surface Finish

The coating applied to the sand casting mold enhances the surface finish of the cast parts. By preventing sand particles from sticking to the mold during the pouring process, the coating allows for a cleaner and more refined surface on the final product. This is especially beneficial for parts where aesthetics or fine detailing is important, such as decorative automotive parts or intricate machinery components.

Improved Durability and Strength

Coated sand casting molds are designed to withstand high temperatures and intense thermal stresses during the casting process. The coatings not only enhance the mold’s structural integrity but also improve its resistance to thermal shock and erosion. This results in longer mold life and greater reliability in high-volume production runs.

Versatility in Application

These molds are highly versatile, capable of handling a wide variety of metal alloys, including ferrous and non-ferrous materials. Whether casting aluminum, steel, or copper alloys, coated sand casting molds provide the flexibility needed to accommodate diverse casting requirements. This versatility makes them ideal choice for industries such as automotive, aerospace, and industrial machinery.

Cost-Effective Production

Despite their advanced performance characteristics, coated sand casting molds offer a cost-effective solution for manufacturers. The molds are relatively inexpensive to produce and can be reused multiple times, dominant to lower overall production costs. Moreover, their ability to reduce waste and scrap further contributes to savings in manufacturing.

Enhanced Process Control

Using coated sand casting molds allows for greater control over the casting process. The uniform coating layer helps regulate the cooling rate of the molten metal, dominant to more consistent results across different batches. This control ensures that each casting meets the required specifications, enhancing overall product quality.

Environmental Benefits

In addition to their performance advantages, coated sand casting molds also offer environmental benefits. The materials used in the mold coatings are often recyclable, reducing the impact on the environment. Furthermore, the improved mold life and reduced waste help lower the overall ecological footprint of the casting process.

Coated sand casting molds provide a reliable, efficient, and cost-effective solution for producing high-quality metal parts. Their precision, durability, and versatility make them an outstanding choice for a wide range of industries, helping manufacturers achieve better results while optimizing production costs.

About Us

Honor

News

-

Industry News 2026-02-13

What Is Coated Sand Casting Mold and How Does It Work? Coated sand casting mold refers to a sand mold that has been coated with a refractory or bindin...

View More -

Industry News 2026-02-06

Valve fittings castings are a core component in fluid control systems across many industries. They are manufactured through casting processes such as ...

View More -

Industry News 2026-01-28

Engineering machinery castings are metal components formed by pouring molten metal into a mold cavity that holds the shape of a required part. This ma...

View More -

Industry News 2026-01-23

Mechanical parts castings are fundamental components in the manufacturing of various products used in industries such as automotive, aerospace, machin...

View More

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch