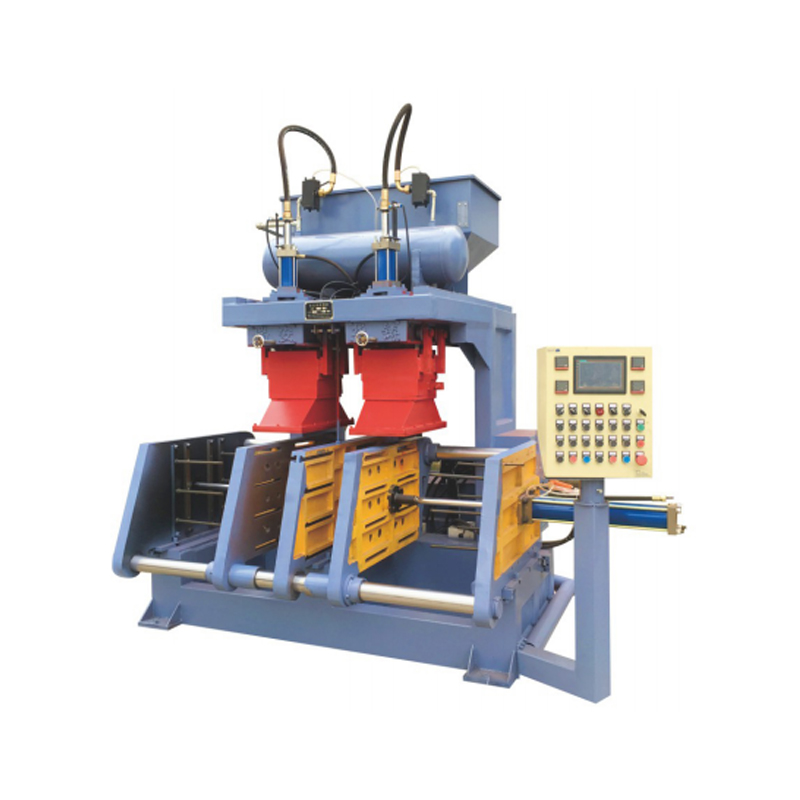

Vertical Parting Core Shooting Machine: Functions and Design

Industry News-Operating Principle and Cycle Sequence

The Vertical Parting Core Shooting Machine automates the process of creating a bonded sand core using the core shooting method. The cycle begins with two core box halves being clamped together in a vertical orientation within the machine. A blow head, filled with resin-coated sand (typically cold-box or hot-box sand), is positioned against the injection port of the closed core box.

High-pressure air, often between 4 to 6 bar, is then introduced into the blow head, fluidizing the sand mixture and forcing it to rapidly fill the cavity of the core box. The sand is compacted into the intricate shape of the intended core. Following the injection phase, the chemical binding process is initiated. For amine-cured cold-box processes, a catalyst gas is purged through the compacted sand to trigger hardening. For heat-cured processes, the core box itself may be heated. After a predetermined cure time, the core box halves unclamp and part vertically. Ejector pins, integrated into the core box, then extend to push the hardened core out of one half of the box. The finished core is removed, often by a robotic arm or conveyor, and the cycle repeats. This sequenced operation—clamp, shoot, cure, part, eject—is controlled by a programmable logic controller (PLC) for consistency.

Key Mechanical Components and Structure

The machine's architecture is built around facilitating the vertical parting action and withstanding the forces involved.

The primary frame is a robust C-shaped or four-column structure that provides the rigidity needed to hold the core box halves in precise alignment during clamping and injection. The clamping unit consists of hydraulic or pneumatic cylinders that generate the force to hold the core boxes tightly shut against the pressure of sand injection. This unit is mounted to facilitate vertical movement. The shooting system comprises a sand magazine or hopper that feeds the blow head. The blow head contains a fluidizing chamber and a shooting plate that seals against the core box. Its precise alignment with the box inlet is critical. The machine also integrates gas dosing systems for catalyst delivery in cold-box processes and an extraction hood to capture and vent fumes generated during curing. All moving components, such as the clamping platens and ejector mechanisms, run on linear guides to ensure smooth, accurate motion.

Typical Applications and Production Context

Vertical parting machines are selected for specific core types and production volumes rather than being a universal solution.

They are particularly suited for cores that are relatively flat or have a dominant parting line that is logical in a vertical plane. Common examples include cylinder head cores, engine block water jacket cores, and large, flat structural cores for industrial castings. The vertical design offers an advantage in gravity-assisted core removal; the finished core can drop or be easily lifted from the parted box onto a receiving conveyor. This makes the design efficient for medium to high-volume production runs where automation is prioritized. The machine footprint is often considered more favorable for certain factory layouts, as the working area is at a convenient height for maintenance and setup. They are less commonly used for very small, complex cores that might be produced in multi-cavity horizontal machines or for cores where a horizontal parting line is more natural to the geometry.

Selection and Operational Considerations

Choosing and operating a vertical parting core shooter involves evaluating several technical and practical factors. The decision matrix often includes comparisons with horizontal parting machines.

|

Consideration Factor |

Vertical Parting Machine Context |

Comparative Note |

|

Core Geometry & Ejection |

Best for cores that can be reliably ejected downward with gravity assistance; flat or shallow-draft geometries. |

Horizontal machines may offer more flexibility for complex, deep-draw cores with side pulls. |

|

Floor Space & Automation |

Often has a smaller floor footprint; facilitates integration with drop-through automation for core handling and cooling conveyors. |

Horizontal machines may require more floor space for core extraction and downstream handling. |

|

Sand Filling Uniformity |

Gravity can assist in sand settling during shooting for certain flat core designs, potentially reducing air entrapment. |

Horizontal machines rely solely on air pressure for fill, which can be an advantage for intricate vertical passages. |

|

Access for Maintenance |

Key components like the shooting head and core box area are typically at an accessible height for tooling change and service. |

Access to the parting line on horizontal machines can sometimes be less direct. |

|

Process Compatibility |

Well-suited for both cold-box and hot-box processes; catalyst gas distribution can be designed for vertical cavity geometries. |

Similarly compatible, though gas purge patterns may differ. |

Beyond this comparison, operational considerations include the required clamping force (determined by projected box area and shooting pressure), the shot weight capacity, and the level of automation for sand filling, core removal, and box cleaning. The compatibility of the machine's control system with upstream and downstream foundry processes is also a factor for integrated production lines.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch