Structural Design Thoughts on Coated Sand Casting Molds

Industry News-Coated sand casting molds, often associated with shell molding and resin-coated sand processes, are widely used in the production of metal parts that require controlled surface quality and dimensional consistency. Compared with conventional green sand molds, coated sand molds rely on resin-bonded sand to form a stronger and more stable mold structure. This difference places higher demands on structural design. Reasonable design helps ensure smooth filling, stable solidification, convenient mold assembly, and reliable casting quality. The following discussion presents several key thoughts on the structural design of coated sand casting molds from different perspectives.

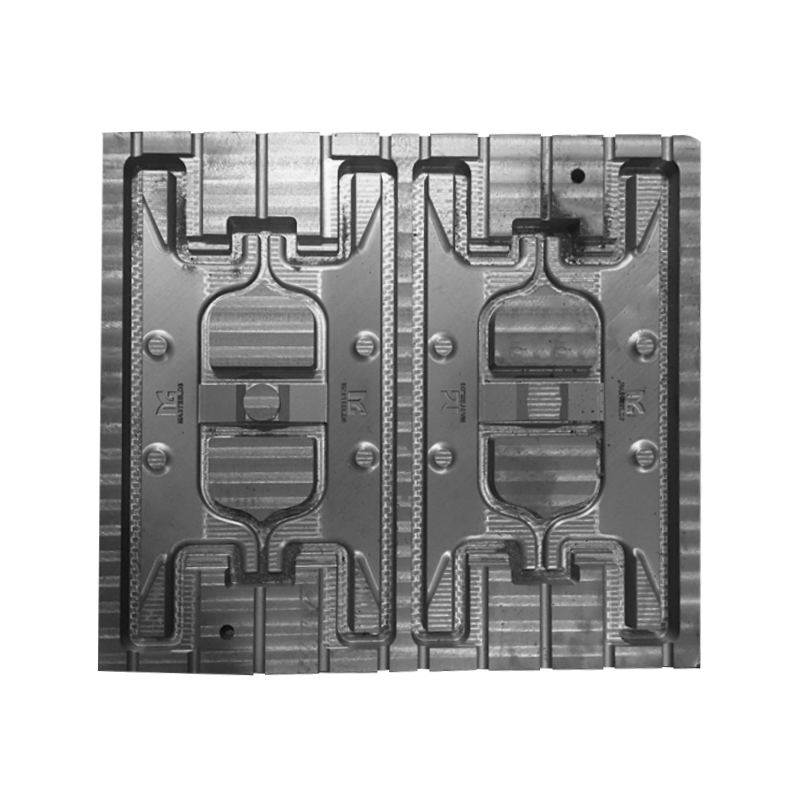

Overall Mold Structure and Parting Design

The overall structure of a coated sand casting mold should be planned with a clear understanding of the casting’s geometry, weight, and functional requirements. Unlike loose green sand molds, coated sand molds often use pre-formed shells or rigid mold halves. This means the structural layout must be determined carefully at the design stage.

One of the considerations is the selection of the parting line. The parting surface should be placed where it allows:

- Smooth separation of the mold halves without damaging the cavity surface

- Convenient positioning of cores

- Simple removal of the casting after solidification

- Reduced need for complex side cores or sliders

The thickness of the coated sand shell also affects the overall structure. If the shell is too thin, it may lack sufficient strength to resist metal pressure during pouring. If it is too thick, material consumption rises and heat dissipation may become uneven. Designers often choose shell thickness based on casting size, wall thickness, and pouring temperature.

In addition, the supporting structure surrounding the shell, such as backing sand or external frames, should be designed to distribute metal pressure evenly. This helps prevent local deformation, shell cracking, or mold shift during pouring.

Gating System and Metal Flow Control

The gating system plays a central role in the structural design of coated sand casting molds. Due to the relatively high strength and smooth surface of resin-coated sand, melt flow behavior differs from that in green sand molds. The gating system should be designed to guide molten metal smoothly into the cavity while limiting turbulence.

Several structural points are commonly considered:

The sprue should be straight and tapered to maintain stable metal flow and limit air entrainment.

The runner system should distribute metal evenly to different cavity sections, especially for castings with varying wall thickness.

The ingates should be positioned to fill thicker sections and promote directional solidification.

In coated sand casting, the smooth inner surface of the shell often faster melt flow. While this can improve filling, it also increases the risk of erosion at the ingates if the structure is not properly reinforced. Therefore, design adjustments such as wider ingates or controlled choke sections are often used.

A well-structured gating system not only affects filling quality but also influences the formation of inclusions, oxide films, and other internal defects.

Venting, Core Design, and Gas Control

Gas control is a key issue in coated sand casting because resin binders release gas during heating. If the mold structure does not provide enough exhaust channels, gas may become trapped and form pores within the casting.

From a structural design perspective, this requires attention to:

Venting paths: Small vent holes or built-in vent channels should be arranged at high points of the cavity to allow air and gas to escape.

Permeability balance: Although coated sand has lower permeability than green sand, the structure must still maintain enough gas discharge capacity.

Core venting: If cores are used, they should include their own venting system to avoid gas accumulation within enclosed spaces.

Core structure also deserves special attention in coated sand molds. Cores are often made from the same resin-coated sand and must match the cavity precisely. Structurally, the cores should have:

- Sufficient strength to resist buoyancy during pouring

- Proper core prints for accurate positioning

- Reasonable wall thickness to balance strength and gas release

Improper venting or weak core design may defects such as gas holes, core shift, or local deformation, even when the outer shell remains intact.

Solidification Control and Feeding Structure

The structural design of the feeding system directly affects the soundness of coated sand castings. Since coated sand molds generally have lower moisture content and different thermal characteristics compared with green sand molds, their heat transfer behavior also differs. This influences how risers and feeders should be placed.

Several structural considerations are commonly applied:

Riser placement: Risers should be positioned near thicker sections where shrinkage is likely to occur.

Feeding path continuity: The metal path from the riser to the hot spot should remain open during solidification.

Insulating sleeves: Where necessary, external insulating materials can be used to slow down riser solidification.

The stiffness of the coated sand shell also affects feeding. Because deformation is limited, shrinkage compensation relies more heavily on proper feeding system design rather than mold expansion. This requires accurate prediction of solidification order and heat concentration areas.

In some cases, chills may be incorporated into the mold structure to locally increase cooling rate and guide the direction of solidification. Their placement must be coordinated with the riser structure to avoid isolated solidification zones.

The structural design of coated sand casting molds requires careful coordination between mold strength, metal flow control, gas discharge, and solidification behavior. From the selection of parting lines and shell thickness to the arrangement of gating, venting, cores, and risers, each structural choice directly influences casting quality and production stability.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch