What are the Main Uses of Mechanical Parts Castings?

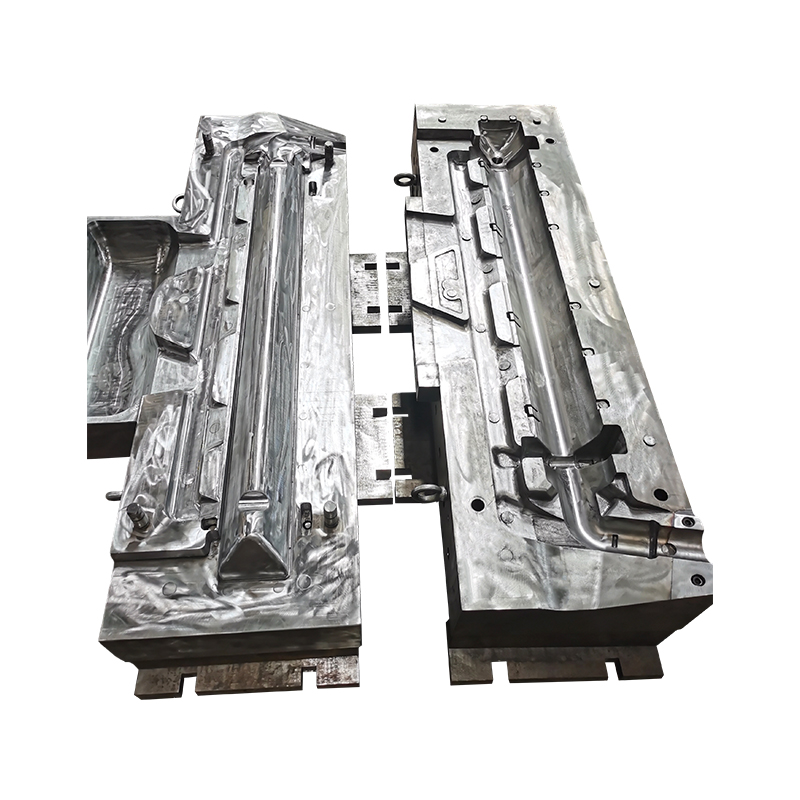

Industry News-The manufactured world is built upon a foundation of components that provide structure, transmit power, and enable motion. Among the most fundamental methods for creating these components is the process of casting, which involves pouring molten metal into a mold to form a specific shape upon solidification. The outputs of this process are known as Mechanical Parts Castings, and they are integral to nearly every sector of industry. These components are valued for their ability to achieve complex geometries, their material integrity, and their cost-effectiveness, especially for medium to high-volume production. The versatility of Mechanical Parts Castings allows them to be found in applications ranging from the engine of a car to the frame of a heavy-duty machine. To understand their widespread adoption, it is useful to explore their primary uses across four key areas: automotive applications, industrial machinery, infrastructure and construction, and consumer goods. The diverse applications of Mechanical Parts Castings highlight their role as essential building blocks in modern engineering.

How Do They Power the Automotive Industry?

The automotive sector is one of the largest consumers of metal castings, relying on them for critical components that ensure vehicle performance, safety, and durability. Within an automobile, Mechanical Parts Castings are present in several key systems. The engine block, a quintessential example, is typically a single, complex casting that forms the foundation for the entire powertrain. Cylinder heads, transmission cases, and differential housings are also commonly produced as Mechanical Parts Castings due to the need for robust, heat-resistant, and intricately shaped parts. Beyond the powertrain, suspension components like control arms and brake calipers are often cast, as the process can create strong, lightweight shapes that withstand constant stress and vibration. The consistent quality and structural integrity offered by high-grade Mechanical Parts Castings are therefore vital for meeting the stringent reliability standards of the global automotive industry. The production of these automotive components represents a primary application for Mechanical Parts Castings.

What Role Do They Play in Industrial Machinery?

In the realm of industrial machinery, the demands for strength, durability, and customization are exceptionally high. Mechanical Parts Castings are employed to create the heavy-duty frames and housings that form the skeleton of machines such as presses, lathes, and agricultural equipment. These frames must be rigid enough to resist deformation under significant operational loads, a requirement that castings can meet effectively. Furthermore, complex gearboxes, pump housings, and hydraulic valve bodies are frequently produced as Mechanical Parts Castings. The casting process allows for the integration of internal passages and mounting features directly into the component, reducing the need for complex assembly and machining. This capability to produce durable, custom-shaped parts makes the use of Mechanical Parts Castings a practical choice for machinery manufacturers who require components that can endure harsh operating environments and continuous use.

How Are They Utilized in Infrastructure and Construction?

The development and maintenance of public and private infrastructure rely heavily on durable and reliable components. In this sector, Mechanical Parts Castings are found in a variety of applications that form the backbone of modern society. Municipal water systems, for instance, use cast valve bodies and pipe fittings due to their corrosion resistance and ability to maintain a seal under pressure. In construction, heavy machinery like excavators and cranes depend on cast components for their structural booms, counterweights, and slewing rings. The manufacturing of these essential infrastructure elements is a key use for Mechanical Parts Castings. Additionally, power generation plants, whether traditional or renewable, utilize specialized Mechanical Parts Castings for turbine housings and generator frames. The long service life and structural capacity of these castings make them suitable for projects that are built to last for decades.

Where Do We Find Them in Consumer and Specialty Goods?

Beyond heavy industry, Mechanical Parts Castings are present in many items encountered in daily life. The field of consumer goods benefits from the aesthetic and functional flexibility of the casting process. For example, the body of a high-quality hand tool, such as a wrench or a vise, is often a durable casting. In the home, cast iron cookware is prized for its even heat distribution, a property inherent to the casting process. Furthermore, many specialty and recreational items incorporate Mechanical Parts Castings. The frames of commercial sewing machines, components of medical devices, and parts for bicycles are all examples where the strength-to-weight ratio and design flexibility of castings are advantageous. Even in the aerospace sector, precision investment castings are used to create lightweight, high-strength turbine blades. This broad applicability across consumer markets underscores the versatility of Mechanical Parts Castings.

In conclusion, the main uses of Mechanical Parts Castings are as diverse as modern industry itself. From the vehicles we drive to the machines that build our world, and from the water systems we rely on to the tools we use at home, cast components provide an indispensable combination of strength, complexity, and economic viability. The continued development and refinement of casting techniques ensure that Mechanical Parts Castings will remain a cornerstone of manufacturing, enabling innovation and supporting infrastructure across the globe. Their pervasive presence is a testament to their fundamental role in shaping the physical landscape of our civilization.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch