What Are The Key Aspects of a Gravity Casting Machine?

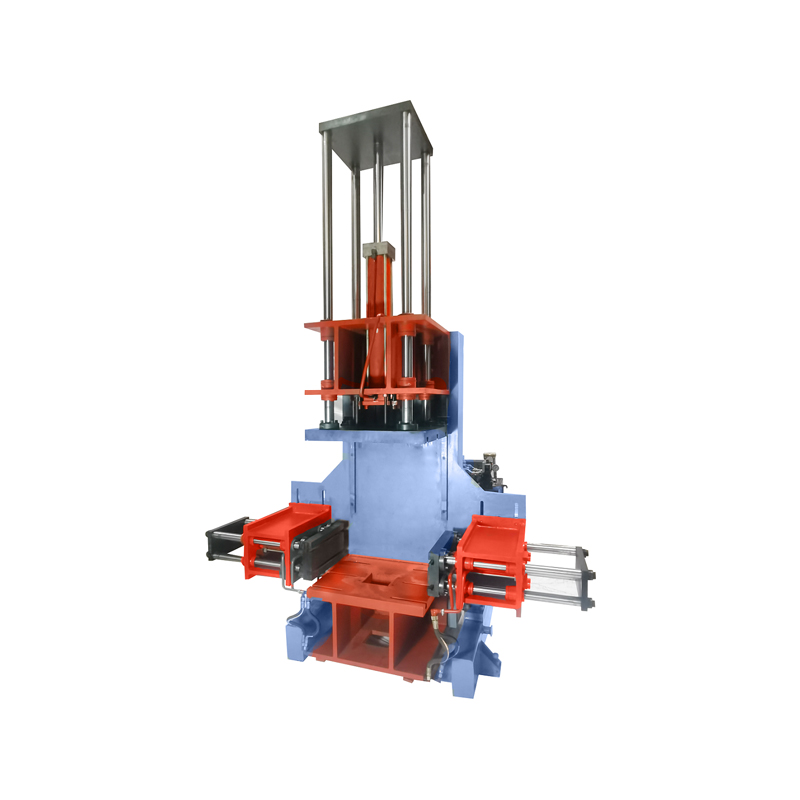

Industry News-Gravity casting machines are widely used in the metal casting industry to produce components with consistent shapes and controlled dimensions. Unlike other casting methods, gravity casting relies on the natural force of gravity to fill molds with molten metal, making it suitable for medium-sized production and materials with moderate melting points. Understanding the characteristics of gravity casting machines can help manufacturers optimize production, reduce defects, and improve efficiency.

How does the gravity casting process work?

Gravity casting machines operate by pouring molten metal into a mold under the influence of gravity. This method does not require additional pressure, simplifying the casting process. Key points include:

- Molten metal flows naturally into mold cavities, filling detailed shapes.

- No external force is applied, reducing equipment complexity.

- Suitable for materials such as aluminum, brass, and zinc alloys.

A small foundry producing aluminum engine components uses a gravity casting machine to create intake manifolds. The natural flow of metal allows the production of complex internal channels without the need for high-pressure equipment, making it suitable for medium-scale batches.

What are the advantages in terms of mold design and flexibility?

Gravity casting machines provide flexibility in mold design and material selection. Features include:

Compatibility with sand molds, permanent molds, and ceramic molds.

Ability to produce components with varying thicknesses and intricate internal cavities.

Easier modification of molds for small batch production or prototyping.

A company producing decorative metal items, such as aluminum lighting fixtures, uses gravity casting to experiment with different mold designs. The ease of adapting molds allows designers to create detailed patterns without investing in high-pressure machinery.

How does gravity casting influence quality and precision?

While gravity casting does not use external force, it can achieve satisfactory quality and precision under proper control. Key points include:

- Uniform filling of molds for consistent component dimensions.

- Reduced risk of turbulence and gas entrapment compared to high-pressure methods.

- Surface finish can be enhanced through controlled pouring and mold preparation.

A manufacturer of brass valves uses gravity casting machines to produce parts with smooth surfaces and precise internal diameters. By carefully controlling pouring speed and mold temperature, they reduce porosity and ensure dimensional consistency.

What are practical considerations for efficiency and cost?

Gravity casting machines can be cost-effective and relatively simple to operate. Key aspects include:

Lower energy requirements than pressure casting methods.

Minimal maintenance due to simpler mechanical components.

Reduced operational costs, making them suitable for small to medium production volumes.

A medium-sized workshop producing aluminum furniture fittings uses gravity casting machines because they provide adequate output with minimal energy consumption and straightforward maintenance. This approach reduces operational expenses while allowing flexibility in production.

Key Aspects of Gravity Casting Machines

|

Aspect |

Description |

Example Use Case |

|

Process Method |

Uses gravity to fill molds with molten metal |

Aluminum intake manifolds |

|

Mold Design and Flexibility |

Compatible with sand, permanent, and ceramic molds; easy modification |

Decorative lighting fixtures |

|

Quality and Precision |

Uniform filling, reduced turbulence, smooth surfaces |

Brass valves |

|

Efficiency and Cost |

Lower energy consumption, minimal maintenance, suitable for medium batches |

Aluminum furniture fittings |

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch