What Are Coated Sand Casting Molds?

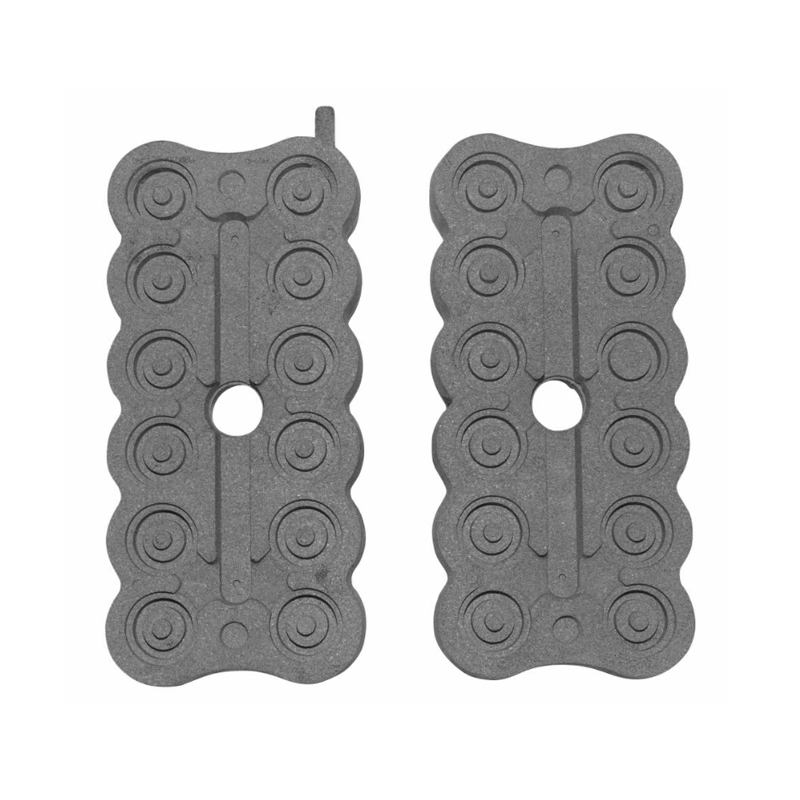

Industry News-Coated sand casting molds are widely used in the metal casting industry to produce parts with better surface finish, dimensional accuracy, and reduced casting defects. The term refers to traditional sand molds that are covered with a thin layer of coating material before molten metal is poured into the mold cavity. This coating improves the performance of the mold during the casting process and enhances the quality of the final product.

Below is a detailed overview of what coated sand casting molds include, how they are produced, and where they are most commonly applied.

1. Composition of Coated Sand Casting Molds

A coated sand casting mold consists of two main parts: the base sand and the coating layer.

Base Sand: The mold is made from silica sand, zircon sand, chromite sand, or other refractory sands bound together with resin or clay binders. The sand gives the mold its shape and strength.

Coating Layer: The coating is a mixture of refractory powders (such as graphite, zircon, or alumina), binders, and solvents. It forms a protective and insulating barrier between the molten metal and the sand.

The coating is applied to the mold cavity and allowed to dry, forming a smooth surface that improves casting quality.

2. Purpose of the Coating

The coating on a sand mold serves several important functions during casting:

Improved Surface Finish: The coating provides a smooth surface that prevents metal penetration into the sand, resulting in a cleaner and finer surface on the cast part.

Reduced Defects: It minimizes gas generation, metal-sand reaction, and burn-on defects, which can otherwise affect the quality of the casting.

Thermal Control: The coating acts as a thermal barrier, controlling the cooling rate of the molten metal and reducing thermal stress or cracking.

Easier Mold Release: The coating prevents the cast metal from sticking to the mold surface, simplifying demolding and cleaning operations.

In short, coatings make sand casting more reliable and help ensure consistent results, especially in precision applications.

3. Methods of Applying the Coating

Several application techniques are used depending on the complexity of the mold and the desired finish:

Brushing or Spraying: For small molds or specific areas, the coating can be applied manually with a brush or sprayed using specialized equipment.

Dipping: In automated foundries, molds or cores are dipped into a coating slurry for full, even coverage.

Flow Coating: This method involves pouring or circulating the coating over the mold surface, allowing it to coat evenly before draining the excess.

After application, the coating is dried using air drying or low-temperature ovens to ensure it forms a firm and consistent layer before metal pouring.

4. Common Types of Mold Coatings

Different types of coatings are used depending on the type of metal being cast and the required surface properties:

Graphite Coatings: Excellent for iron and steel castings; provide a smooth surface and good heat resistance.

Zircon Coatings: Used for nonferrous alloys like aluminum or magnesium, offering strong resistance to metal penetration.

Alumina or Silica Coatings: Applied where high refractoriness and thermal insulation are required.

Water-Based or Alcohol-Based Coatings: Water-based coatings are environmentally friendly and safer to handle, while alcohol-based coatings dry faster and are suitable for high-volume production.

Selecting the right coating type is crucial for achieving the desired casting performance and quality.

5. What Are The Advantages of Coated Sand Casting Molds

Coated molds offer multiple benefits compared with uncoated sand molds:

Enhanced Surface Quality: The finished cast part has a smoother and more precise surface.

Reduced Cleaning and Finishing Work: Since fewer defects occur, post-casting grinding or polishing is minimized.

Improved Dimensional Accuracy: The coating helps maintain consistent metal flow and solidification.

Better Mold Life: The protective layer prevents erosion and thermal damage to the mold.

Lower Scrap Rates: Fewer defects mean more usable parts, improving productivity.

These advantages make coated sand casting molds an efficient and economical choice for manufacturers who seek high-quality cast components.

Coated sand casting molds are used in industries that require accurate and high-quality castings, such as:

Automotive: Engine blocks, cylinder heads, and gearbox housings.

Aerospace: Lightweight structural parts with complex geometries.

Machinery: Components like impellers, housings, and brackets.

Energy and Marine: Turbine blades, pumps, and propeller components.

Their versatility and reliability make them valuable for both ferrous and nonferrous metal casting operations.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch