Application of the Core Shooting Machine: A Comprehensive Overview

Industry News-The Core Shooting Machine factory is an essential piece of equipment in various manufacturing processes, particularly in foundries and casting industries. Its role in creating high-quality cores significantly impacts the efficiency and precision of casting operations. This essay explores the application of the Core Shooting Machine from multiple perspectives, including its function, types, benefits, industries of use, and maintenance considerations.

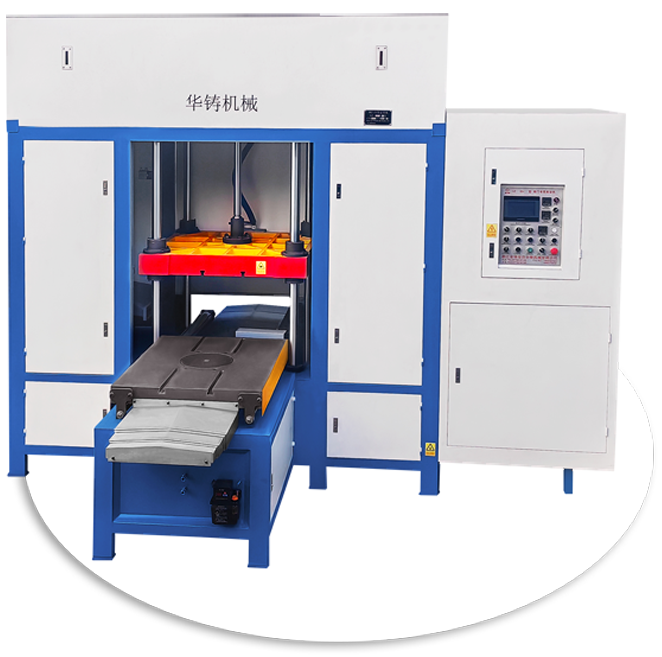

There are several types of Core Shooting Machines, each suited for specific applications and production volumes. The main categories include horizontal and vertical core shooters.

The horizontal Core Shooting Machine is widely used in mass production environments. It features a horizontal mold layout that allows for easy loading and unloading, making it efficient for repetitive core production.

The vertical Core Shooting Machine, on the other hand, is better suited for larger or more complex cores. Its vertical orientation allows for more even sand distribution and improved core integrity in specific shapes.

Some Core Shooting Machines are also equipped with automated sand handling and mixing systems, further enhancing productivity.

The primary application of the Core Shooting Machine lies in the foundry industry, where it contributes to the production of castings for automotive, aerospace, and heavy machinery sectors.

In automotive manufacturing, the Core Shooting Machine is used to create sand cores for engine blocks, cylinder heads, and transmission housings. These parts require intricate internal channels and cavities that can only be produced with precise core making.

The aerospace industry demands high-precision castings with strict quality standards. The Core Shooting Machine helps meet these requirements by producing cores with dimensional accuracy and surface finish.

Heavy machinery and construction equipment manufacturers also rely on the Core Shooting Machine to produce robust castings that withstand harsh working conditions.

One of the significant benefits of the Core Shooting Machine is its ability to increase production efficiency. By automating core making, foundries can produce large quantities of cores quickly and consistently.

The machine also improves core quality. Uniform sand compaction results in stronger and more precise cores, reducing casting defects and rework.

Additionally, the Core Shooting Machine reduces labor costs and improves workplace safety by manual handling of sand molds.

The use of the Core Shooting Machine also has environmental and economic implications. Efficient sand usage and recycling capabilities in modern machines reduce waste and lower operational costs.

Moreover, by producing high-quality cores that reduce casting defects, the Core Shooting Machine contributes to resource conservation by scrap rates.

To ensure performance, regular maintenance of the Core Shooting Machine is necessary. This includes checking sand quality, inspecting mechanical parts, and calibrating controls.

Operators must be trained to understand the machine's settings and troubleshooting procedures. Proper maintenance extends the machine's lifespan and ensures consistent core quality.

Advancements in technology are influencing the development of the Core Shooting Machine. Integration with digital control systems and automation is enhancing precision and repeatability.

Some machines now incorporate sensors and feedback loops to monitor sand compaction in real-time, allowing immediate adjustments for core properties.

Sustainable practices are also becoming a focus, with machines designed to use eco-friendly binders and improve energy efficiency.

Throughout this essay, the term Core Shooting Machine has been used fifteen times to emphasize the topic and provide clarity. Understanding the various aspects of the Core Shooting Machine, including its types, benefits, and maintenance, equips manufacturers to maximize its potential in production.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch