How about Coated Sand Casting Molds: Composition and Functions?

Industry News-In metal casting, the quality of the mold is critical to achieving precision, durability, and surface finish of the final product. Coated sand casting molds are widely used in foundries due to their unique composition and functional advantages. These molds combine a traditional sand base with a special refractory coating to improve mold performance. Understanding their composition and functions provides insight into why coated sand molds are preferred in many casting operations.

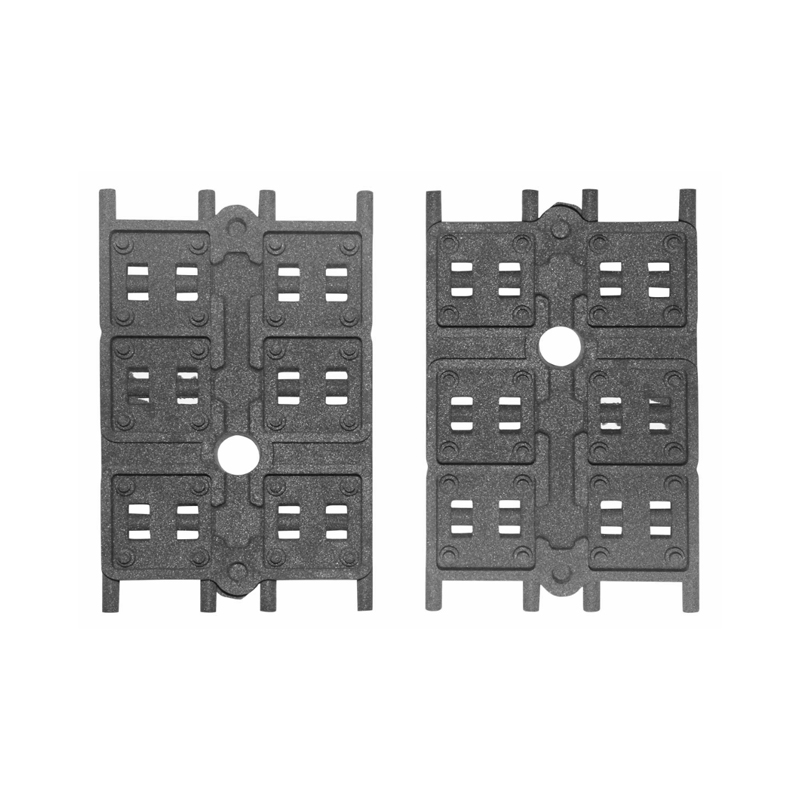

Composition of Coated Sand Casting Molds

Coated sand casting molds are essentially sand molds treated with a thin layer of refractory coating. The main components and their roles can be broken down as follows:

|

Component |

Description |

Purpose |

|

Base Sand |

Usually silica sand, sometimes olivine or zircon sand |

Provides the main body of the mold; offers thermal resistance and structural support |

|

Refractory Coating |

Fine refractory powders mixed with binders and solvents |

Forms a protective layer that improves surface finish, reduces metal penetration, and withstands high temperatures |

|

Binder |

Organic or inorganic binding agents |

Holds sand grains together in the mold structure and supports the coating layer |

|

Additives |

Anti-flash, anti-sticking, or surface-enhancing materials |

Enhances mold performance by reducing defects such as sticking, sand burn-on, or rough surfaces |

Explanation:

The sand provides the mold’s shape and thermal stability, while the refractory coating protects the sand during metal pouring. Binders keep the sand compact, and additives improve mold reliability and final casting quality.

Functions of Coated Sand Casting Molds

Coated sand casting molds serve multiple functions that improve both the production process and the quality of castings. These functions can be expanded as follows:

Improved Surface Finish

The refractory coating provides a smooth surface between the molten metal and the sand.

Reduces surface roughness, sand burn-on, and the need for extensive post-casting finishing.

Ideal for castings where appearance and dimensional accuracy are important.

High Thermal Resistance

Coated sand molds withstand high pouring temperatures without degradation.

Protects the sand core from premature erosion or collapse during metal pouring.

Allows the mold to maintain shape and support larger, more complex castings.

Reduced Metal Penetration

The coating acts as a barrier, preventing molten metal from seeping into the sand grains.

This reduces defects such as penetration marks or rough textures on the casting surface.

Enhanced Mold Strength

The combination of sand and binder provides structural rigidity.

The coating layer further reinforces the mold, helping it withstand mechanical stresses during handling and pouring.

Ease of Mold Removal

The coating creates a thin layer that separates the metal from the sand.

After solidification, the casting can be removed more easily without damaging the mold or the product.

Adaptability for Complex Designs

Coated sand molds can reproduce intricate patterns, fine details, and thin sections.

The coating allows for precise replication of surface features, making them suitable for automotive, aerospace, and industrial components.

Advantages in Manufacturing

Higher Quality Castings: Smooth surfaces and minimal defects reduce post-processing costs.

Efficiency: Refractory coatings allow faster pouring and shorter cooling times in some applications.

Durability: Molds can handle repeated use in some semi-permanent processes, depending on material choice.

Versatility: Suitable for a wide range of metals, including iron, steel, and non-ferrous alloys.

Coated sand casting molds combine a sand base with a refractory coating to create a mold capable of producing high-quality castings. Their composition includes base sand, refractory coatings, binders, and performance-enhancing additives. Functionally, they improve surface finish, prevent metal penetration, provide thermal resistance, and allow for precise replication of complex shapes. These molds are widely used in industries where casting quality, durability, and efficiency are essential.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch