Horizontal parting core shooting machine structure operation

Industry News-Horizontal parting core shooting machine structure operation

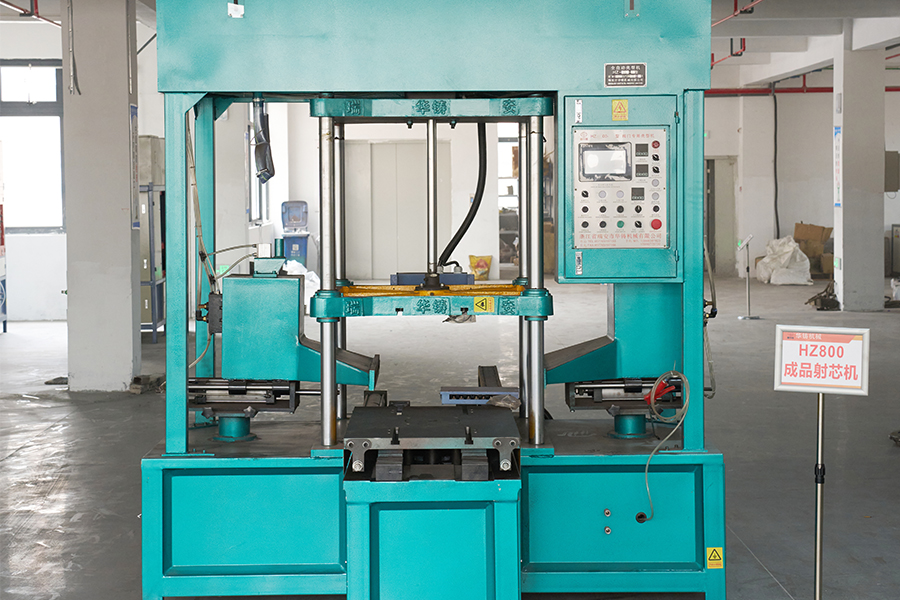

The core shooting machine is a PLC-controlled operating system and can also be used manually. The working principle is to shoot the coated sand into the heated mold core. The sand core is preheated in the core box and triangulated to a certain thickness before being taken out to form a sand core product with a smooth surface and accurate size.

Operation instructions: First, close the mold—press—exhaust—release the shooting head—scrape the sand—curing—open the mold—take the core, single cycle operation.

Core shooting machines are essential pieces of equipment in industries such as foundries, automotive, and metal casting. These machines are used to create molds or cores for casting metal parts, and they play a crucial role in ensuring precision and efficiency. When considering the purchase of a core shooting machine, two important factors come into play: the price of the machine and the specific features offered by different types, such as the fully automatic horizontal parting core shooting machine.

The price of a core shooting machine can vary widely depending on several factors, such as the manufacturer, machine type, complexity, and capabilities. On average, prices can range from a few thousand dollars for simpler, manual or semi-automatic machines to several hundred thousand dollars for high-tech, fully automated models.

For entry-level machines, such as manual core shooters, the price is generally more affordable, typically ranging from $10,000 to $50,000. These machines may have fewer features and require more manual labor to operate, but they still serve their purpose in small to medium-scale operations.

On the other hand, advanced machines, especially fully automatic core shooters, can command much higher prices. These machines are equipped with features, such as automatic molding, precise temperature control, and fast cycle times. The price for such models can range from $50,000 to $300,000 or more, depending on the brand and the specific features. These machines are ideal for large-scale industrial production, where speed, precision, and consistency are critical.

Fully automatic horizontal parting core shooting machines are advanced models that provide high efficiency, precision, and automation for core production. Unlike traditional vertical core shooters, horizontal parting core shooters work by parting the core horizontally. This offers several advantages in terms of mold design and core accessibility.

A fully automatic horizontal parting core shooting machine operates with minimal human intervention. Once the mold or core material is loaded into the system, the machine automatically mixes, shoots, and hardens the mold, all within a set cycle time. This type of machine often features a high degree of flexibility, allowing users to produce a wide range of core shapes and sizes without needing significant retooling.

The main advantage of horizontal parting core shooting machines lies in their ability to produce complex and intricate molds with greater precision than manual machines. The fully automatic nature of these machines also better consistency across large batches, reducing human error and improving overall quality.

These machines are equipped with modern control systems that offer precise control over the process parameters such as temperature, pressure, and curing time. This ensures that each core produced is uniform and meets the required specifications.

One of the key factors that sets fully automatic horizontal parting core shooting machines apart from other models is their productivity. These machines are designed for high-volume production and can significantly reduce cycle time. This makes them ideal for industries with large-scale manufacturing needs, such as the automotive and aerospace sectors, where precision and speed are paramount.

While the initial cost of a fully automatic horizontal parting core shooting machine may be higher compared to manual or semi-automatic machines, the long-term benefits in terms of productivity and product quality make them a worthwhile investment. The reduction in labor costs, coupled with increased throughput and consistency, helps businesses justify the initial expenditure over time.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch