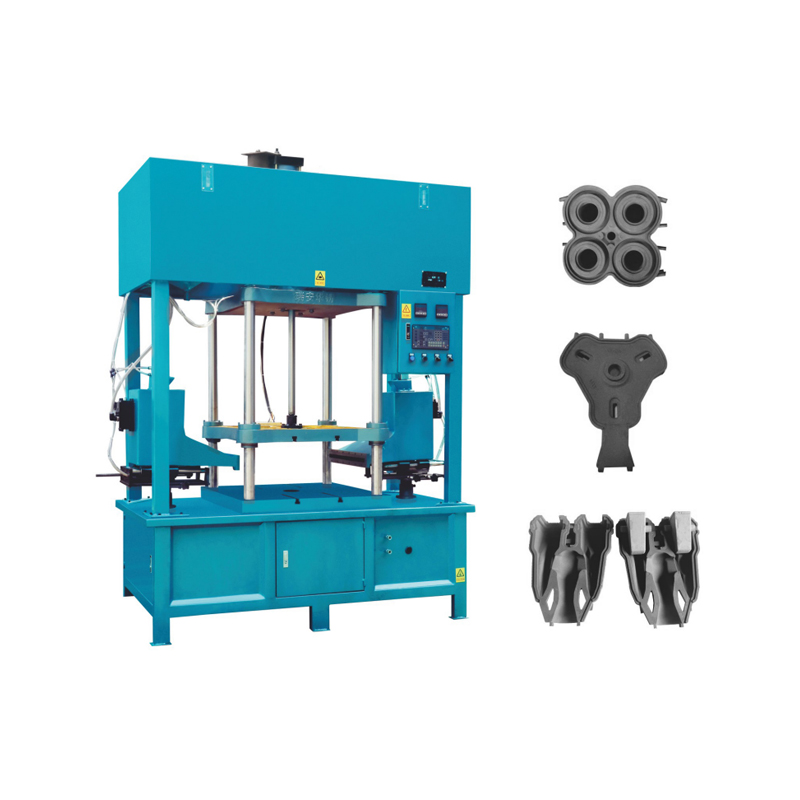

Double Head Core Shooting Machine: Enhanced Productivity and Precision

Industry News-The double head core shooting machine is a specialized piece of equipment designed to improve the efficiency and productivity of the core-making process. This machine features two independent shooting heads, allowing it to create two separate cores simultaneously. By doubling the output in each cycle, it significantly reduces the overall time required to produce cores, making it an ideal solution for high-volume production lines.

The double head core shooting machine operates similarly to a standard core shooting machine but with the added advantage of two heads that function independently. The process begins with the preparation of the sand-binder mixture, which is loaded into the machine. Each head is equipped with its own mold chamber, and the machine simultaneously shoots the sand-binder mixture into both chambers. The mixture is compacted under pressure, forming two cores in one cycle. After curing, the cores are ejected, and the process is repeated.

Benefits of the Double Head Core Shooting Machine

Increased Productivity: By producing two cores at once, the double head core shooting machine doubles production capacity without the need for additional labor or equipment.

Reduced Cycle Time: The simultaneous core production reduces overall cycle time, allowing manufacturers to meet tight production deadlines and handle larger order volumes.

Improved Efficiency: This machine optimizes resource use, particularly in high-demand environments where large quantities of cores are needed. By speeding up the core-making process, it enhances overall manufacturing efficiency.

The double head core shooting machine is widely used in industries that require the production of metal parts with complex internal features. This includes the automotive industry for producing engine components, aerospace for turbine blades, and heavy machinery for manufacturing durable equipment parts. Its ability to handle large production volumes while maintaining precision makes it an essential tool for high-demand manufacturing environments.

The compact structure core shooting machine operates on the same basic principles as larger core shooters, but with a design optimized for smaller spaces. It features a more compact shooting chamber, reduced footprint, and streamlined components. The machine is capable of producing high-quality cores with precision, using a mix of sand and binder. The mixture is injected into the mold under pressure, forming a core that is subsequently ejected after the curing process.

Despite its smaller size, the compact machine still incorporates many of the advanced features found in larger core shooting machines, such as automated processes, precise control systems, and efficient cooling mechanisms.

Benefits of the Compact Structure Core Shooting Machine

Space-Saving Design: One of the significant advantages of the compact structure core shooting machine is its small footprint. This machine is ideal for facilities with limited space, as it can be easily integrated into smaller production areas without compromising on performance.

Energy and Cost Efficiency: Smaller machines tend to consume less energy compared to their larger counterparts. The compact design also often results in lower maintenance costs, making it an economically viable choice for smaller manufacturers or those with lower production volumes.

Precision and Quality: Despite its small size, the machine still delivers high precision in core production. This ensures that even smaller-scale parts, which often require intricate designs, are produced with the same level of accuracy as larger components.

Flexibility for Small Runs: The compact structure core shooting machine is good for businesses that require flexibility in production volumes. It can easily handle both prototype runs and small to medium batch production, making it highly versatile.

En

En

русский

русский Español

Español عربى

عربى Deutsch

Deutsch